A knife plate for a combined stamping-cutting machine: it is a machine equipment that mainly affects its versatility and efficiency, which combines many functions, such as metal cutting, stamping, cutting sheets and bending.

It is widely used in the production of batteries for various electronic products, such as mobile phones, tablet computers, laptops, etc. It mainly divides the materials of lithium batteries into the corresponding dimensions and forms for further processing and use. The principle of operation is that the upper cutting head makes a reciprocating movement through a cutting bar with an electric drive, and the lower cutting head is fixed to complete the cutting work. Compared to the traditional manual method of cutting, a blade for cutting for lithium batteries play an important role in many areas, and their high efficiency, durability and high quality trimming make them an indispensable tool in modern industrial production.

Usually they are made of highly chubs of cast iron or nickel solid alloy with extremely high wear resistance and impact resistance. They evenly mix the concrete in a forced mixer, rotating at high speed, and at the same time withstand friction and strokes of materials with wear -resistant blades for the mixer with extremely high wear resistance and impact resistance.

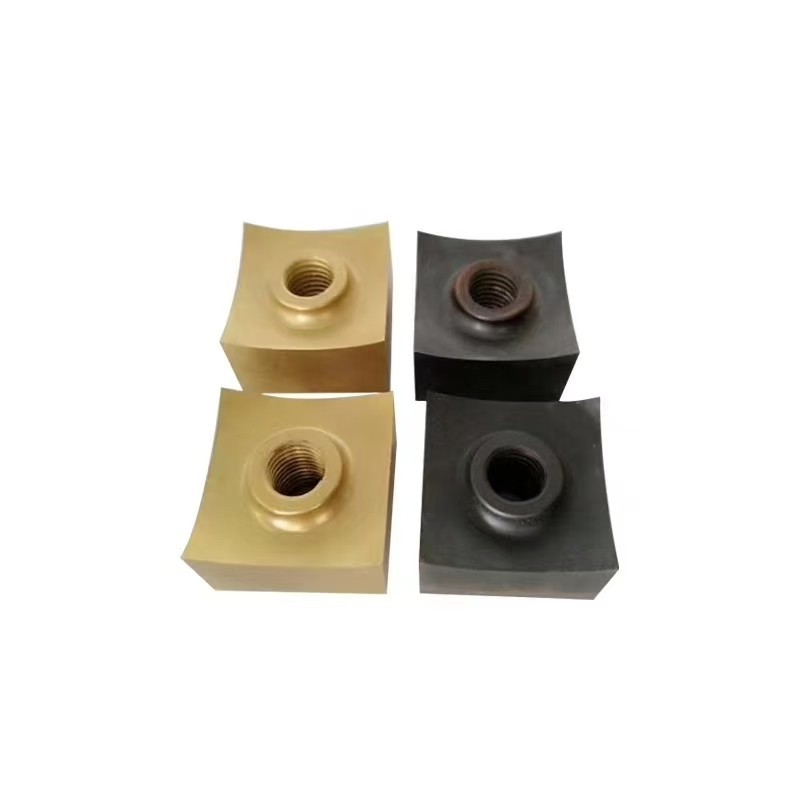

It is mainly used in the line of longitudinal cutting of metal sheets and lanes and is suitable for large plants for the production of steel, factories for the production of steel pipes, factories for the processing of non -ferrous metals, factories for the production of strapping materials, factories for the production of packaging materials, service centers for the processing of steel sheets, plants for the sorting of steel, factories for the production of strip steel, factories for the production of striped steel, factories. manufacturers of cars for longitudinal cutting, etc. The main materials of the rolling scissors knives are SKD, SKH, T10, 6CRW2SI, CR12MOV, LD, H13, W18CR4V and other high -quality instrumental steel and highly alloy molding steel, which are made during vacuum heat treatment to ensure uniform hardness and accuracy of processing.

The use is mainly associated with the correction of metal materials to ensure straightforwardness and surface quality. Correct rolls play an important role in the process of smelting of steel, especially in the production and editing of middle and thick sheets. The basic principle and functions of the correct rolls: the correct rolls return the metal material to a direct state, applying external effort to it. When the material is bent and deformed under the influence of temperature or other factors in the process of production, the correct rolls restore the straightness of the material by applying the amendment force, which forces it to be plastically deformed. The calculation of the amending effort is based on the theory of bend in the mechanics of materials, taking into account factors such as the elasticity module, turnover, thickness and width of the material.

Light industry: In light industry, scissors are usually used to cut materials such as paper products, plastics and film. Aviation industry: In the aviation industry, scissors are used to cut and process various materials in the process of production of aircraft. Shipbuilding: In shipbuilding, scissors are used for cutting various metal materials, such as steel sheets, steel pipes, etc.

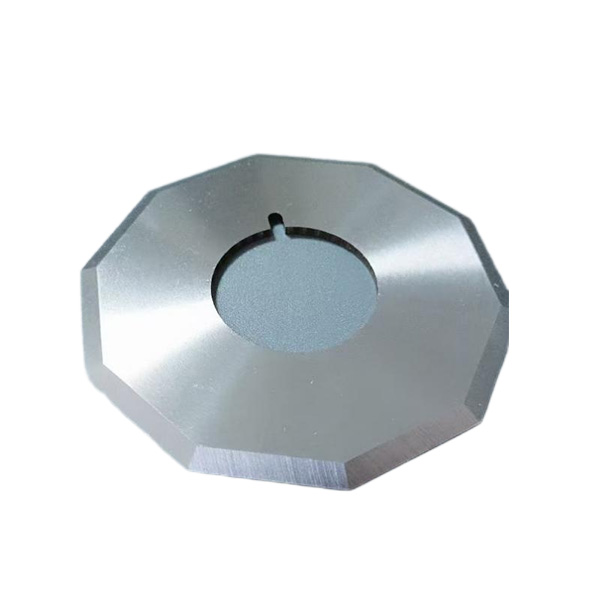

It is mainly used for longitudinal cutting of paper, ribbons, magnetic tape, film, gold, silver, copper, aluminum, alloy foils and other items, is widely used in various industries, such as paper, paper tube, cardboard, leather, rubber and plastic, pipes cutting, carpentry, electronics, films, gold, silver foil, copper foil, and copper foil, copper. Foil, aluminum foil, magnetic tape, and other items of gaps, common materials include 9CRSI, CR12MOV, W6MO5CR4V2, W18CR4V, etc. These materials have good wear resistance and hardness. The heat treatment process is one of the key factors for ensuring the productivity of the blade, through heat treatment can additionally improve the hardness and durability of the blade.

It is used at the metal disposal factory, at the car dismantling factory, in the melting and foundry industry, it is mainly used in industry for recycling and processing waste, in small and medium steel plants for various forms of cross -section, such as round steel, square steel, channel steel, angular steel, palatry beam, steel leaf, steel sheet, steel steel steel, steel steel steel. Pipes and other scrap metal with cold scissors, cutting processing, scissors of all types of metal materials, such as light and thin steel material, steel rod, steel sheet, nickel sheet, round steel, steel pipes and other steel materials.

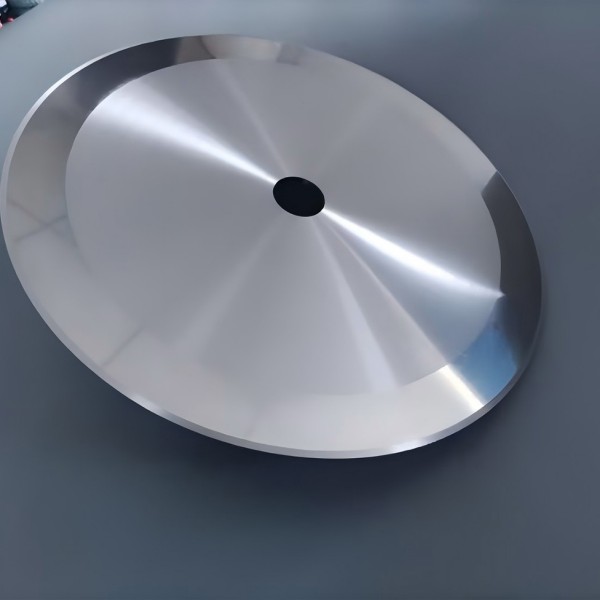

It has a wide range of application in many areas, mainly including the processing of waste mass, metals, wood, paper and other materials. The blades of a one chopper usually consist of a cutting head and blades. The cutting head is the main part of the blade, usually round.

LLC Maanshan Intuns Car production Main business : Large rotating knives for cutting paper