Giliotin knives grinding: process subtleties

Gilloutine grinding is an important stage in the work of any enterprise where this equipment is used. The productivity, safety and durability of the guillotine cut directly depends on the quality of grinding. Incorrectly honed knives lead to marriage, reduce the speed of work and can cause injuries. Therefore, the correct grinding is not just a technical process, but a guarantee of uninterrupted work and staff protection.

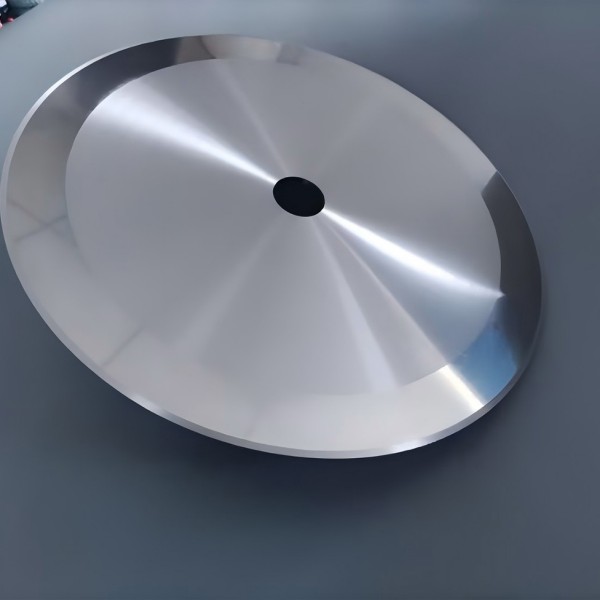

The choice of the right tool and material

For grinding knives, guillotine needs special tools. This is not just sandpaper. The granularity, the type of abrasive, as well as the design of the grinding machine are important. The choice depends on the type of steel from which the knives are made, and on the desired cut quality. As in any other work, a professional approach and a competent choice of tool is a key point. If the knives are made of particularly strong steel, then the abrasive should be appropriate hardness. The incorrectly selected material can ruin the knife, and lead to a deterioration in the quality of the cut.

Grinding technology: important nuances

It is important to observe the exact technology. This implies certain stages of processing, using different grain of abrasive, to achieve the perfect profile and severity. It is necessary to take into account the angle of sharpening, which should correspond to the type of material that will be cut. It is the angle of the cutting edge that determines the quality of the cut and the accuracy of the cut. It is also important the correct location of the knife during grinding to avoid overheating and deformation. A professional approach is important to avoid problems in the future. The experience and knowledge of technology is important here.

Quality control and prevention

After grinding, it is necessary to carry out thorough quality control. This includes checking the severity of the blade, the evenness of the cutting edge and compliance with the established parameters. The use of special measuring tools will identify deviations and take measures. Regular prevention of knives is an equally important point. Preventive grinding and sharpening must be carried out regularly in order to avoid a sharp decrease in the quality of cut and breakdowns, this will also reduce the likelihood of injuries. Constant monitoring of the condition of the knives is the key to a long and effective work of Guillotin.