Steel for knife guillotine for metal

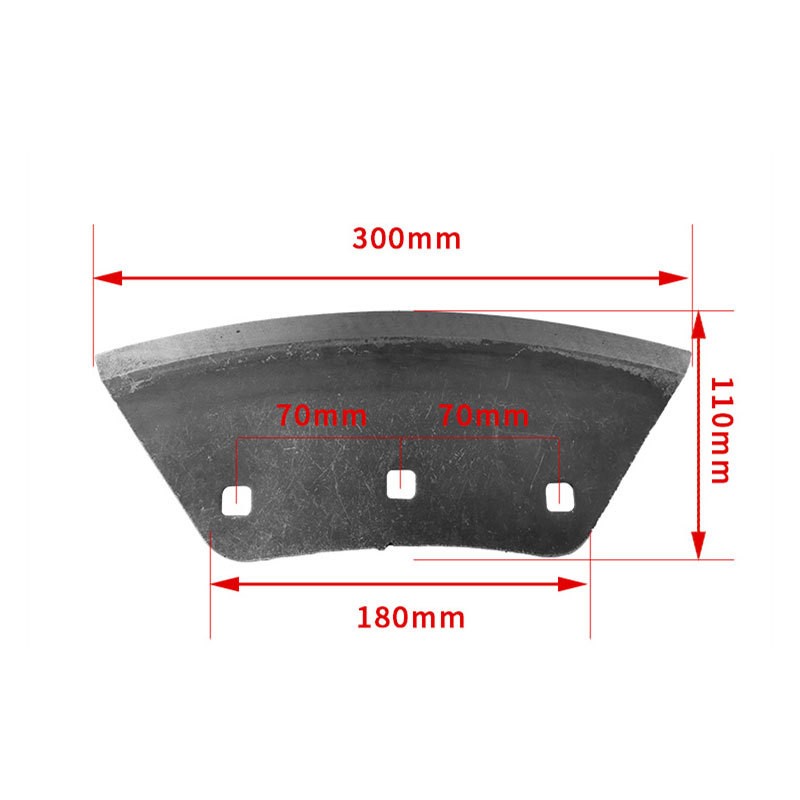

Metal guillotine is a tool familiar to many who work with metal. She cuts metal sheets with high accuracy and speed. The key element of this machine is, of course, a knife. Namely, the steel from which it is made. The efficiency, durability and safety of the guillotine depends on the quality of this steel.

The selection of steel: from strength to wear resistance

The choice of correct steel for a knife of guillotine is an important stage. Steel must have high bending and compression strength to withstand pressure during cutting. No less important is wear resistance. The knife should maintain sharpness and geometric shape for as long as possible, so as not to require frequent replacement. Therefore, steel should be resistant to wear in contact with metal. Different types of metals that are cut on guillotine also require the selection of suitable steel for a knife. For example, stainless steel requires a different material for a knife than soft varieties.

The influence of the structure of steel on durability

The structure of steel is another important factor. Certain alloying additives and heat treatment form a structure that affects the strength, hardness and plasticity of the knife. For example, the presence of chromium increases the corrosion resistance of steel, which is especially important in media with high humidity. The correct structure also contributes to the uniform distribution of voltage in the knife, which reduces the likelihood of its breakdown. It also depends on this structure how easy the knife will keep sharpness, and also how long it will last.

Modern technologies and prospects

Modern technologies allow you to create steel with improved characteristics. Scientists and manufacturers are constantly working on the development of new alloys that combine high wear resistance, strength and relative plasticity. This makes it possible to increase the life of the knives and increase the efficiency of guillotine. The quality of the processing and geometry of the knife itself, which should be in perfect consent of steel for the best results, is also of important. The future of guillotine is undoubtedly associated with new, improved steels for its knives, which will eventually lead to greater performance and lower maintenance costs.