Knives for metallurgy and rental steel

Metallurgy and rolling steel are complex, but interesting processes that require special tools. One of the key elements of this process is knives. They play an important role, ensuring the accuracy, quality and effectiveness of the entire production. Imagine a huge roll of steel that needs to be divided into the necessary pieces - without sharp and reliable knives, this is impossible.

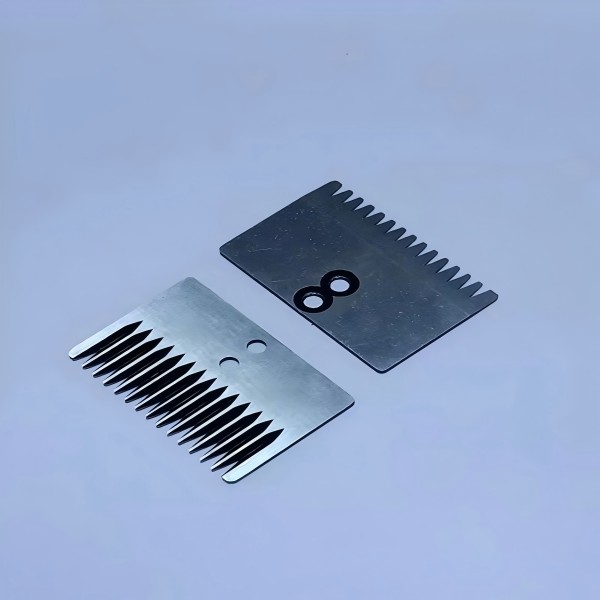

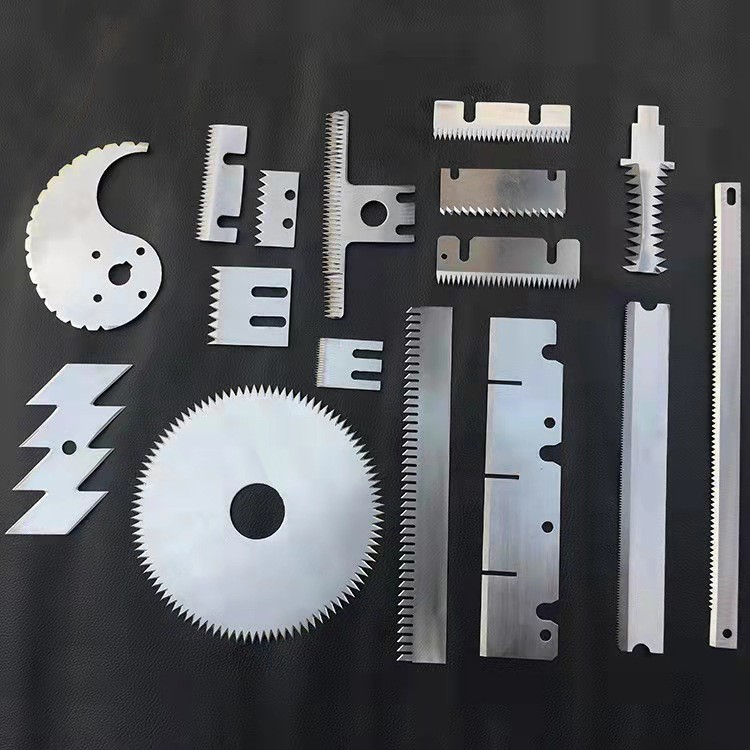

Varieties of knives and their purpose

In metallurgy and rental, knives of various types and structures are used. There are knives for cutting hot and cold steel, knives for processing thin sheet and super -strength alloys, as well as special knives for high -speed cutting. They differ in the material of manufacture (for example, high -strength steel, solid alloys), the shape and thickness of the blade, as well as the mounting method. Each type of knife is sharpened for a certain type of steel and task. Knives for hot steel, for example, should withstand high temperature and strong mechanical loads.

Factors affecting the choice of knives

When choosing knives for metallurgy and rental, steel must take into account many factors. It is important that the knife corresponds to the thickness and type of processed steel. The strength and durability of the knife are critical parameters, since the performance of the entire process depends on them. The speed of cutting, the possibility of using various devices and, of course, the price also play an important role in making a decision. The knife should be not only effective, but also economically profitable. For example, for high -speed cutting, special knives are needed, designed for high speeds and loads, which can cost more than standard ones.

Care and maintenance of knives

Proper care and regular maintenance of knives is the key to their long and effective work. Regular sharpening, checking the condition of the mount and timely replacement of worn parts allow you to significantly extend the life of the knives. This, in turn, reduces production costs and improves the quality of finished products. It is also important to observe safety precautions when working with knives, especially when working with hot steel, since high temperatures can be dangerous for staff. Ultimately, the proper care of knives is the key to the successful operation of the metallurgical and rolling workshop.