Plastic crushers knives

Grinding plastic is a difficult task that requires the right tool. The main element of any crusher is, of course, knives. They are the very teeth that turn pieces of plastic into smaller fragments. How to choose the right knives? Let's figure it out.

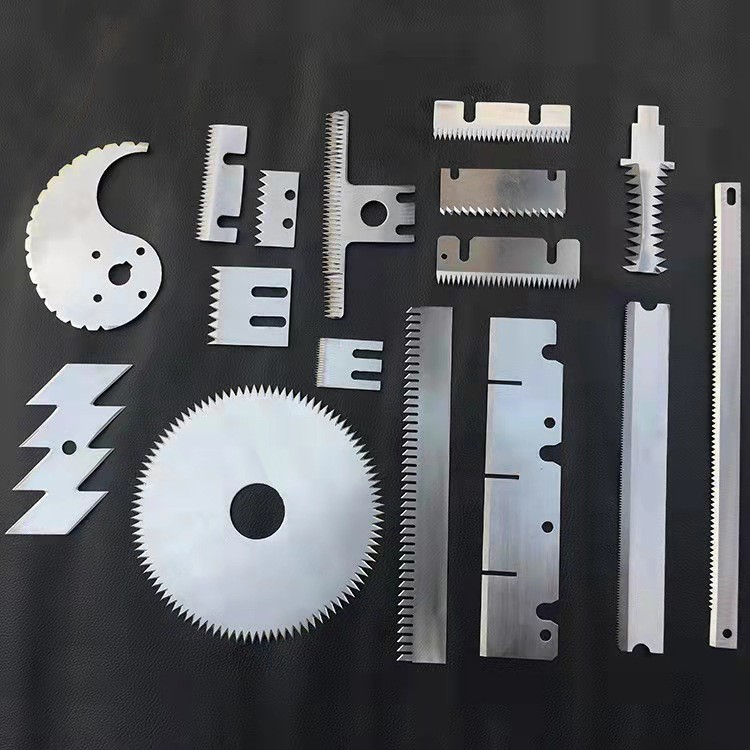

A variety of forms and materials

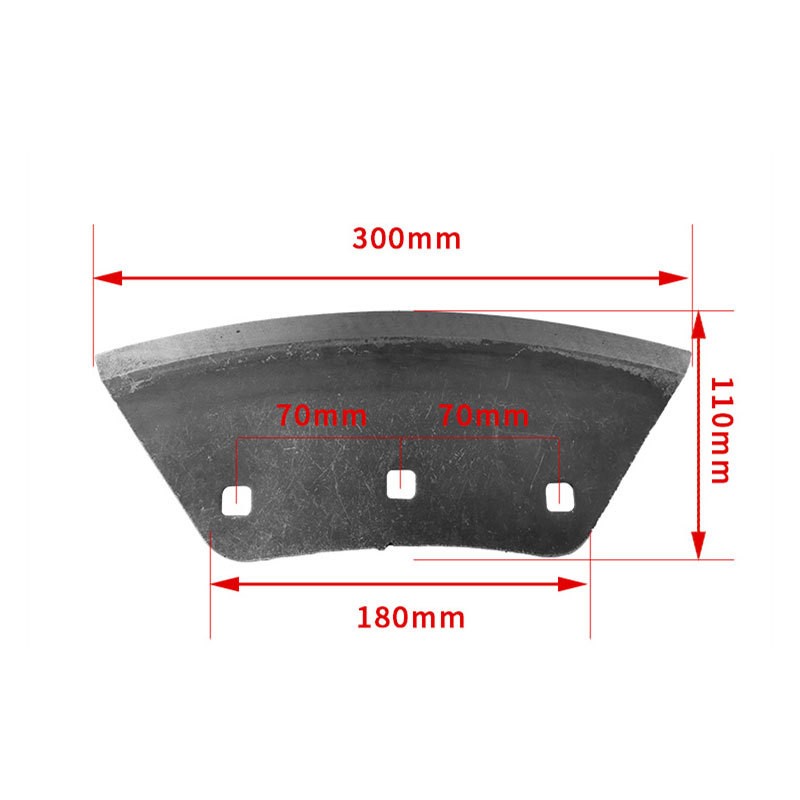

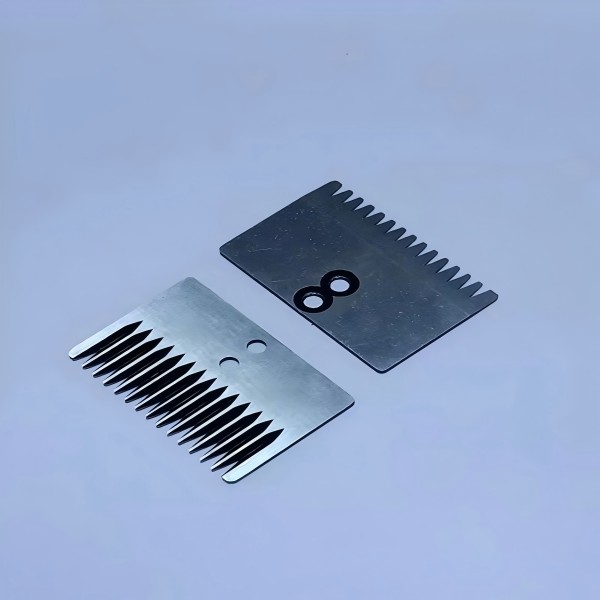

Plastic crusher knives differ in shape and material. There are knives with straight, wavy and even gear edges. The choice depends on the type of plastic, which needs to be chopped. For fragile types of plastic, for example, polyethylene, knives with sharp, but not too aggressive edges are suitable to avoid damage and excessive wear. For more durable materials, for example, polypropylene, you may require more rigid and strong knives, with a hardy coating that can withstand increased load. The material of the knives is also important. Often, high -strength steels are used, hardened for long -term service and resistance to wear.

Important: resistance to wear and security

The main requirements for knives are their wear resistance and safety. Knives should withstand a constant load when working with plastic. They should be resistant to deformations so that the crusher works for a long time and effectively. After all, if the knives quickly dull or break, all the work is going on a drain, and investing in the crusher becomes unprofitable. It is also important that the knives are protected from excessive wear and overheating. Safety is a key point. Protective screens and locks should be reliably installed to prevent contact with moving parts of the crusher. Proper installation and regular maintenance of knives directly affect the safety of work.

How to choose the right knives for your task

When choosing knives, you need to take into account the characteristics of the plastic that you need to process. Different types of plastic require different levels of knife aggressiveness. For example, if you work with large pieces of hard plastic, you will need more powerful knives. If you process a large number of small plastic waste, knives should be optimized under high performance. Pay attention to the experience and recommendations of the manufacturer of the crusher - they will select the optimal knives that are suitable for your equipment and needs. Consult with experts to make the right choice, this will help to avoid problems in the future and will allow you to get the maximum effect of the crusher.