Plastic crushers knives

Plastic crushers knives are important, although often invisible, constituting the process of plastic processing. They perform a key function, grinding waste to the desired size, then allowing the source material to use the source. Imagine a huge bunch of plastic bottles, bags and containers. Without knives that are easy to cut and crushing these materials, this whole process would be impossible.

Types of knives and their features

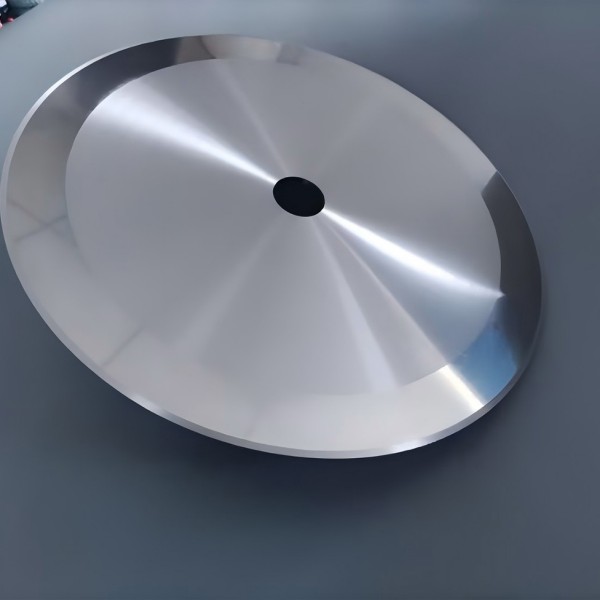

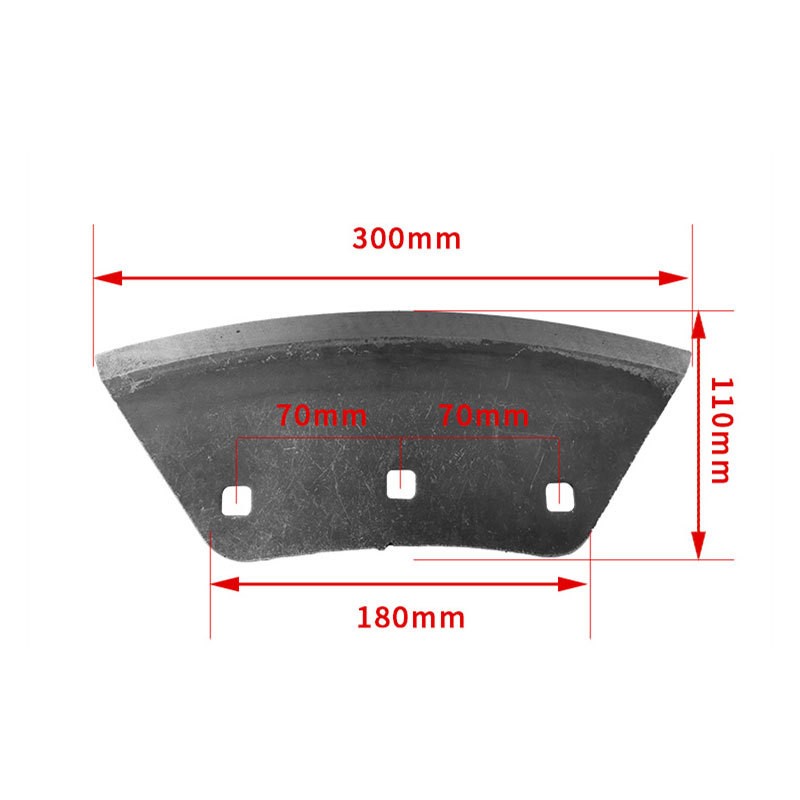

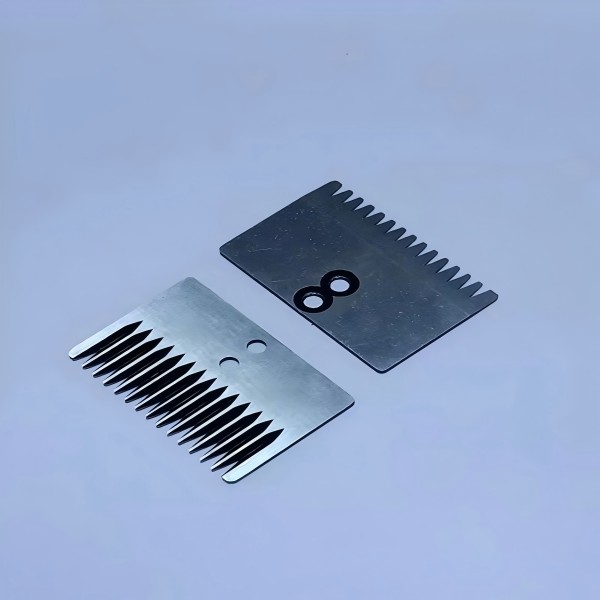

There are many different types of crushers knives, each of which is designed to work with a certain type of plastic. High-strength steel knives have proven themselves, capable of withstand intense loads and aggressive properties of plastic, whether it be PET but, polyethylene or other types. Knives with cutting edges of various shapes provide uniform grinding and maximum output of high -quality secondary raw materials. Knives can also vary in their form and design - from simple to complex ones, with self -maintenance systems, which significantly increases their durability and effectiveness. Some knives are equipped with additional elements to prevent jamming and breakdowns.

The choice of knives is an important point

The correct choice of knives is a key factor for the effective and safe operation of the crusher. It is necessary to take into account the type of processed plastic, the capacity of the crusher and, of course, the budget of the enterprise. If the knives are selected incorrectly, then they quickly fail. As a result, the processing process slows down, and the costs increase. Professional processing consultants will be able to help in choosing suitable knives, given all these factors. A good manufacturer always provides a guarantee for their knives, which allows enterprises to be confident as the services provided.

Knife care

Like any tool, plastic crushers require regular care. Proper storage and timely sharpening or replacement of knives guarantee the durability and safety of equipment. Regular checking of knives for damage, chips and wear will prevent breakdowns, as well as reduce the cost of repair and replacement of equipment. In general, timely and proper care significantly increases the life of the knives, which directly affects the economic efficiency of the entire process.