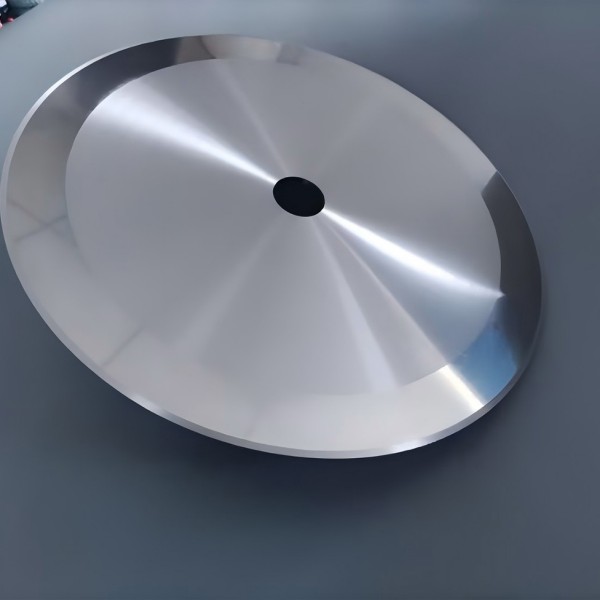

Round steel rod blades

Cutting steel rods is the task that many are faced with metalworking. The final result directly depends on the accuracy and quality of the cutting tool - even sections, the lack of damage and saving the material. Modern blades for this task are developed taking into account various factors, providing maximum performance and durability. Let's look at the main aspects of choosing suitable blades.

Choice of the blade: take into account the diameter and material of the rod

Different rods are different requirements. For example, thin rods require blades with a more acute edge and less weight to avoid bending during cutting. For thick rods, more durable blades are needed that can withstand heavy loads. In addition to the diameter, it is also important to take into account the material of the bar. Steel of different hardness requires different types of blades. Soft steel can be cut with a simpler tool, while for processing more solid rods you need blades with a special coating that increases resistance to wear. It is important to understand that the inappropriate blade can lead to its rapid breakdown, as well as to damage the rod itself - this means that the process will become not only slow, but also unnecessarily costly.

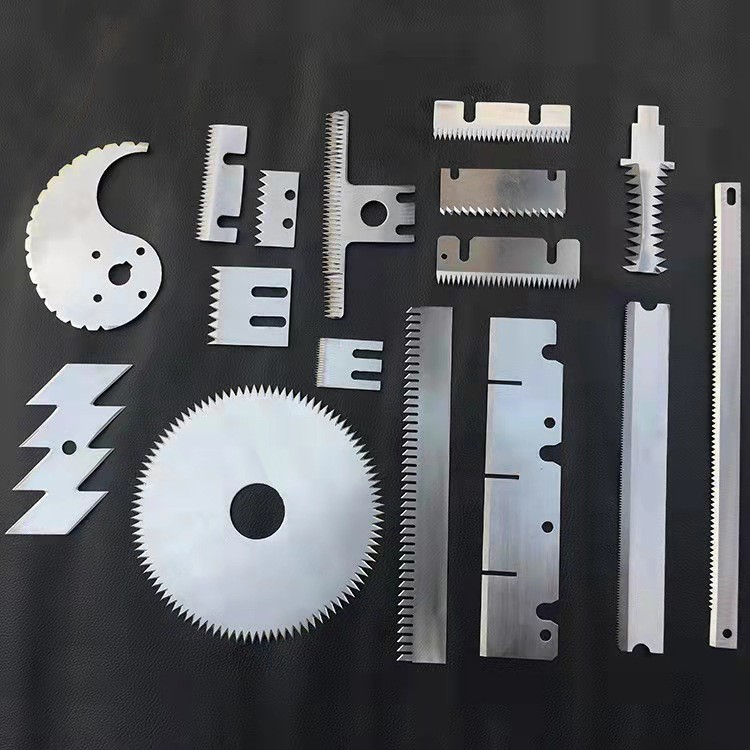

Types of blades and their advantages

Various types of blades are presented on the market: diamond, ceramic, from high -speed steel. Diamond blades are highly resistant to wear and are suitable for cutting a variety of materials, including solid steel. Ceramic blades provide accurate and even sections, but they can be more sensitive to shock. High -speed steel blades are the average option, balancing between value and quality. The correct choice depends on a specific task and budget.

Care for blades and extending their service life

For the maximum service life of the blades, certain rules should be followed. It is necessary to correctly install the blade in the cutting device in order to avoid overloads. Regular lubrication of cutting surfaces also plays an important role in maintaining their condition. It is important to avoid cutting blades, as this can lead to a breakdown of the tool and damage to the processed material. In general, the right approach to choosing and caring for blades is the key to successful and effective work with round steel rods. Do not forget that high -quality blade is the key to a long and economically profitable work.