Blade for low -speed crushers

Low -speed crushers are indispensable assistants in various sectors, from agriculture to waste processing. Their effectiveness directly depends on the quality and proper choice of blades. These small but important details perform a complex task - grinding solid materials. Imagine many small, sharp knives working in tandem to turn pieces of raw materials into smaller particles. The choice of suitable blades is a key moment for the uninterrupted operation of the entire crusher and its long service.

Blade material - the basis of strength

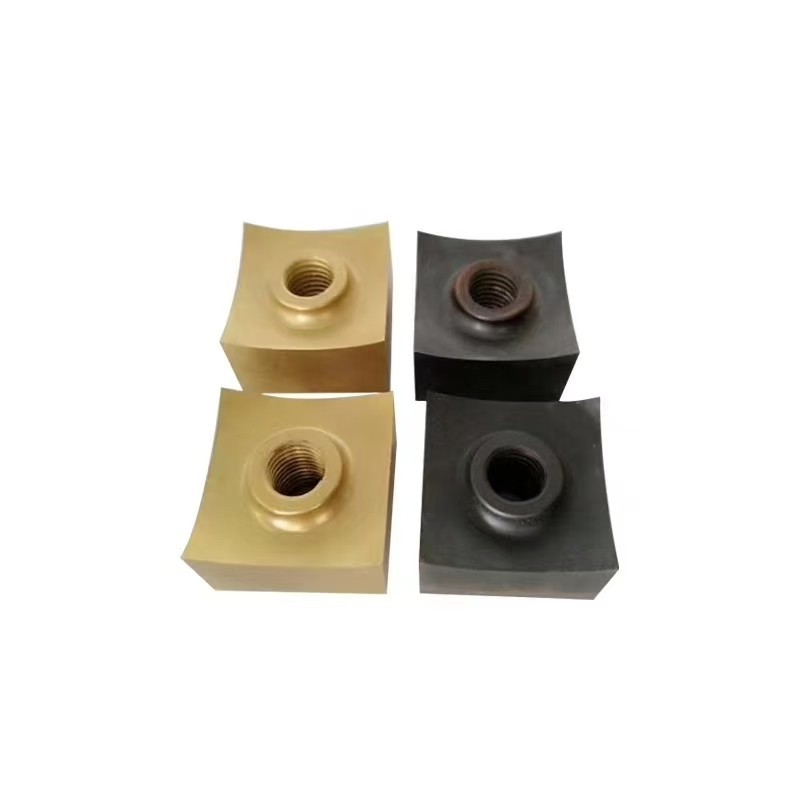

Blaves for low -speed crushers are made of various materials, each of which has its own advantages and disadvantages. The most common steels with a high carbon content, due to their strength and durability. However, these steels may require more care and more frequent replacement. More modern options, such as alloy metals, have high wear resistance, but may have a higher cost. The choice of material depends on the type of material processed and the load intensity on the crusher. For fragile materials, for example, plastic, milder blades may be required to avoid breakdowns.

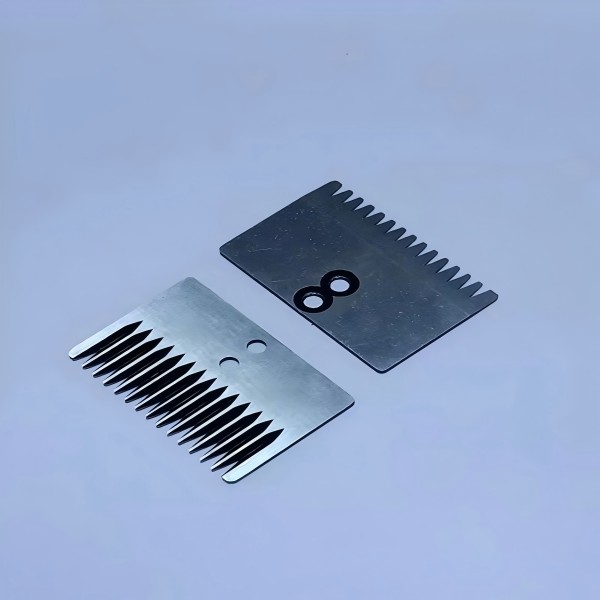

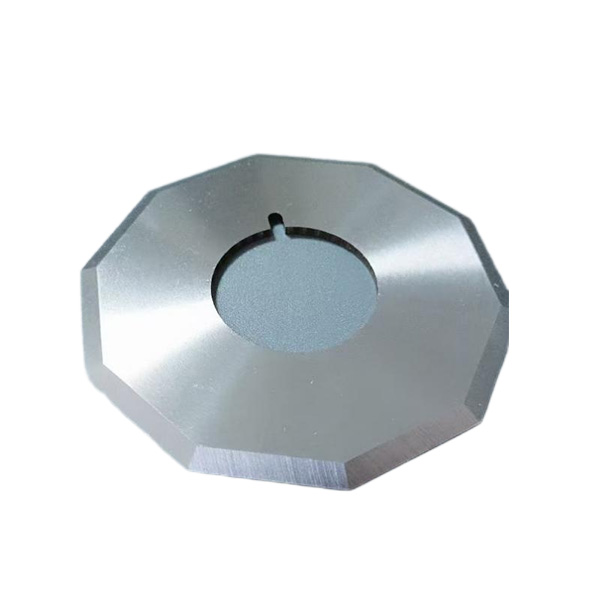

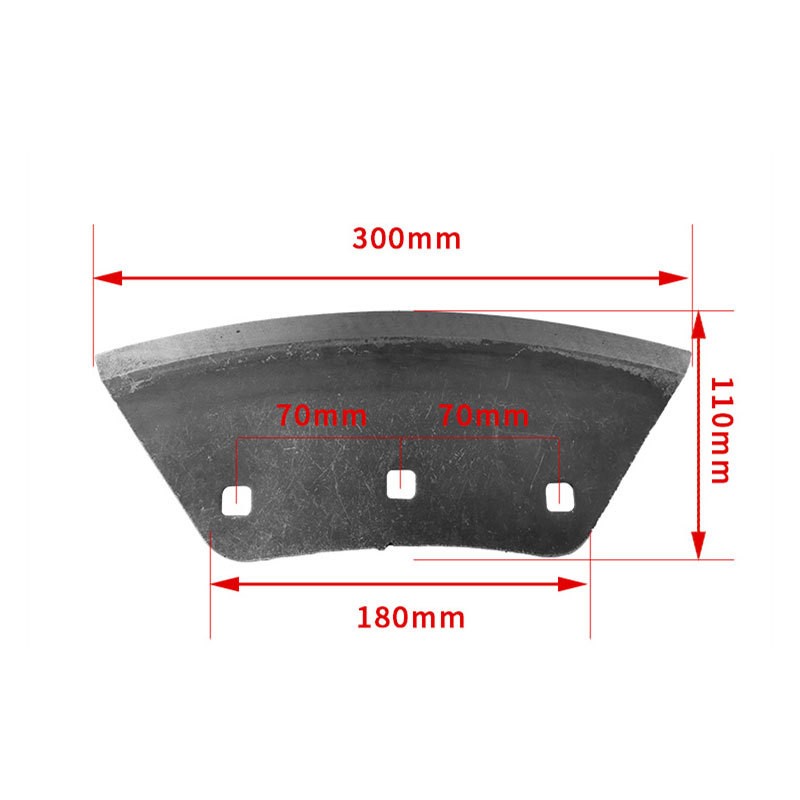

Form of blades - a key factor in efficiency

The shape of the blades also has colossal value. The optimal geometry provides high -quality grinding, evenly distributing the load on the blades. Crivisity, angle of sharpening, thickness - all these parameters affect the performance and durability of the tool. The wrong form can lead to premature wear, jamming and even breakdown of the crusher. It is important to choose blades designed specifically for a specific crusher model in order to ensure maximum efficiency and safety.

Care and replacement of blades - the key to a long work of the crusher

Proper care of the blades is the key to their long service. Regular lubrication, cleaning of adhering materials and timely replacement of worn blades - a guarantee of uninterrupted operation of the crusher. Do not neglect these simple, but important measures. The replacement of blades is best carried out in compliance with the recommendations of the manufacturer, this will help to avoid damage to the crusher and ensure maximum processing efficiency. Pay attention to the recommendations for replacement to avoid potential problems and premature failure of the crusher.