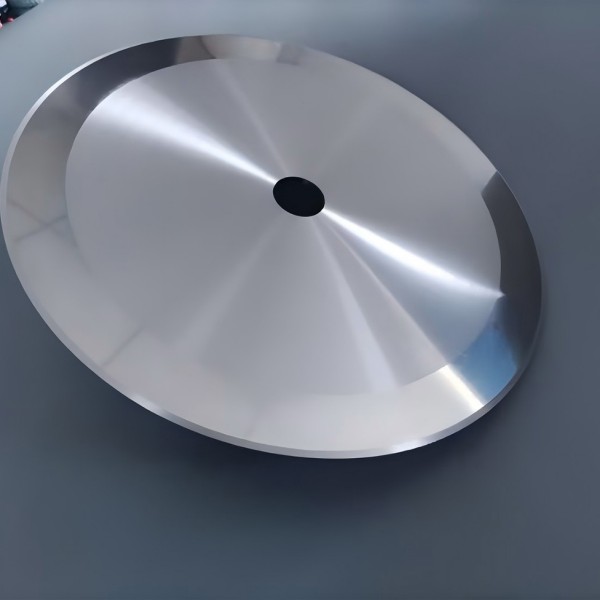

Blade for jugging wood

Peeling of wood is a difficult task that requires certain tools. The main element in this work is a blade, the quality of which directly depends on the efficiency and speed of the process, as well as the safety of the processed material. The right choice of blade is the key to a successful and comfortable process.

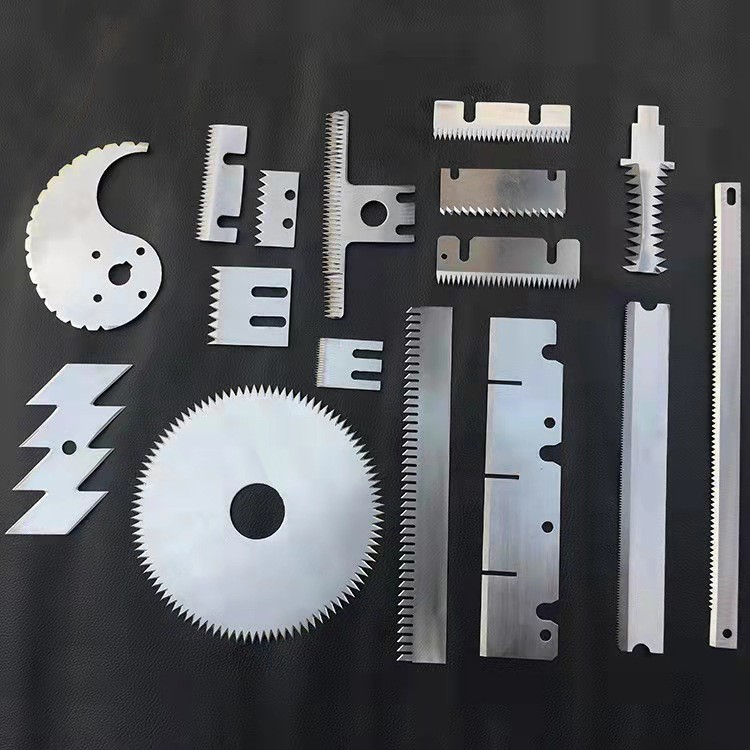

Types of blades and their features

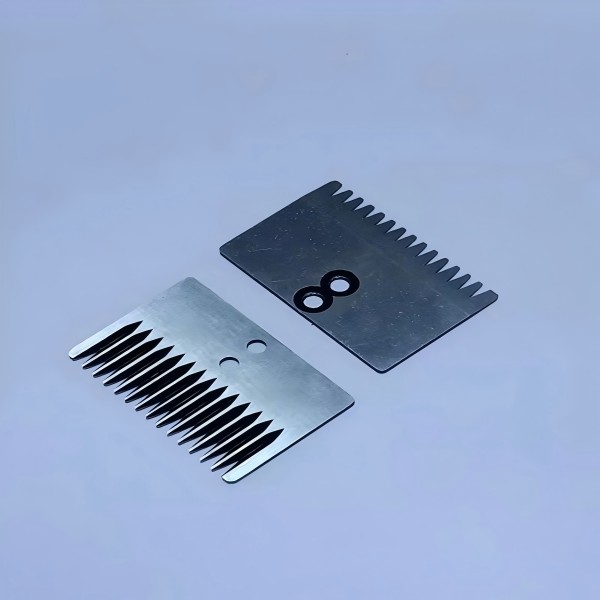

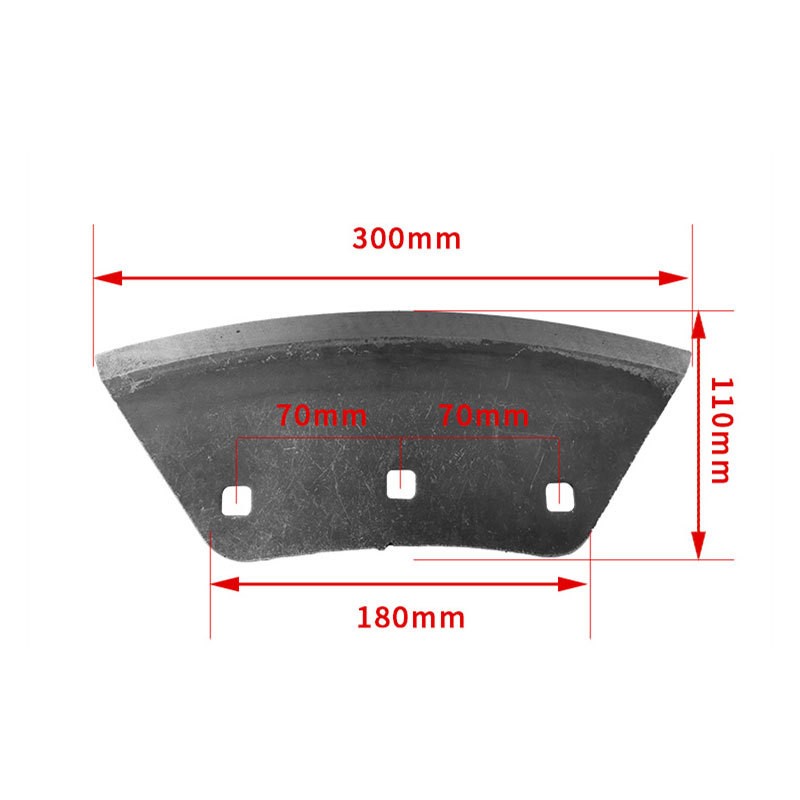

There are many types of blades adapted for different types of wood and tasks. Some blades are designed for thin and neat peeling, others for more rough processing. An important factor is the material from which the blade is made. For example, high -quality steel provides greater strength and durability, which allows you to use the blade longer without replacement. And softer materials, although it can be cheaper, require more frequent replacement. The shape of the blade is also important: straight blades are suitable for simple peeling, and curved for complex contours.

The choice of blades depending on the tasks

When choosing a blade, you need to take into account the specifics of the work. If you need to process a large amount of material in a short time, it is better to choose a blade with a larger area of the cutting surface. To process valuable wood, requiring a special delicate approach, you will need a thinner and acute blade. Remember that a blunt blade can damage the processed wood, reduce the speed of work and require an application of greater power. The correct choice of blade will avoid additional problems and save time and energy.

Blade care for maximum performance

To extend the service life of the blade, proper care is necessary. After each work, the blade must be cleaned of wood sawdust and chips. Regular sharpening of the blade can significantly increase its service life and work efficiency. Do not forget about safety measures when handling sharp blades. Storage of the blade in specially designed cases will prevent random damage and injuries. Subject to these simple rules, the blade will serve you for a long time and efficiently.