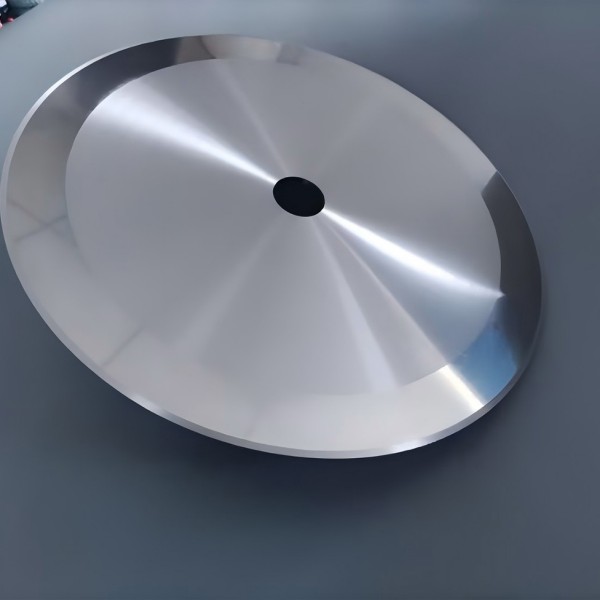

Tough blades

Tough blades are tools that at first glance seem simple, but their design hides amazing effectiveness. Imagine a saw, a knife, or even part of the mechanism - all of them can have gear edges. These tiny protrusions, or teeth, play a decisive role in how the tool interacts with the material.

The function of the teeth

The teeth create more the surface of the contact with the processed material. Instead of smoothing the material, like a smooth blade, a gear blade? Cuts? him in parts. This allows you to cut or grind solid materials like wood, metal or plastic with greater ease. The larger and more acute the teeth, the more effective the tool. Imagine small files that work, cutting the material into separate particles.

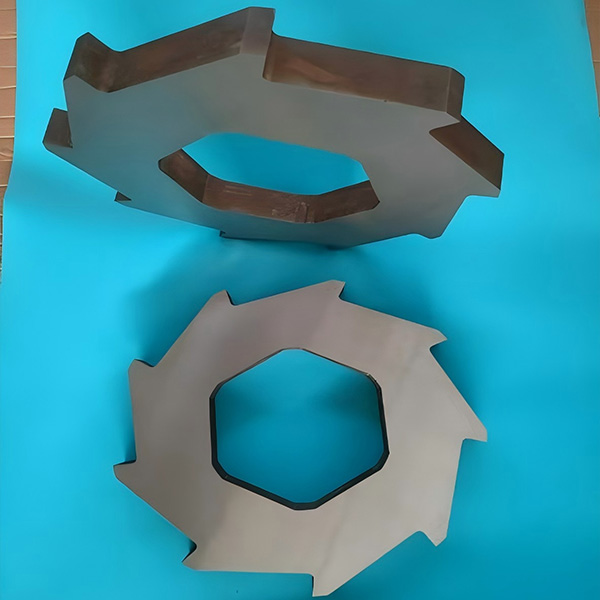

A variety of forms and applications

Tough blades are found in an incredible variety of forms and applications. From miniature mills in time mechanisms to huge blades in industrial equipment. Each type of teeth is adapted for a specific task. Some teeth are created for smooth cuts, others for grinding, and others for sharp and clear cuts. For example, a wood saw has other teeth than a saw for metal. Different types of teeth, in fact, make tools so effective for different tasks.

Care for gear blades

To maintain the optimal effectiveness of gear blades, proper care is necessary. It is important to regularly clean and tighten the tool. Sharp and clean teeth will allow you to work more efficiently and accurately. Regular maintenance will not only extend the life of the tool, but also increase safety during operation. After all, a dumb tool is more difficult to control, which can lead to injury. As a result, careful attitude to gear blades is the key to their long and productive work.