Dressers' spare parts: repair and reliability

Crushes are indispensable assistants in various industries, from mining to the processing of building materials. They grind the materials to the desired fraction, ensuring the efficiency and speed of technological processes. But, like any technique, crushers require periodic care and replacement of parts. The correct choice and timely replacement of spare parts is the key to uninterrupted and long work, as well as saving funds.

The main types of penstrack spare parts

Despite the variety of crushers models, the main spare parts can be divided into several categories. These include:

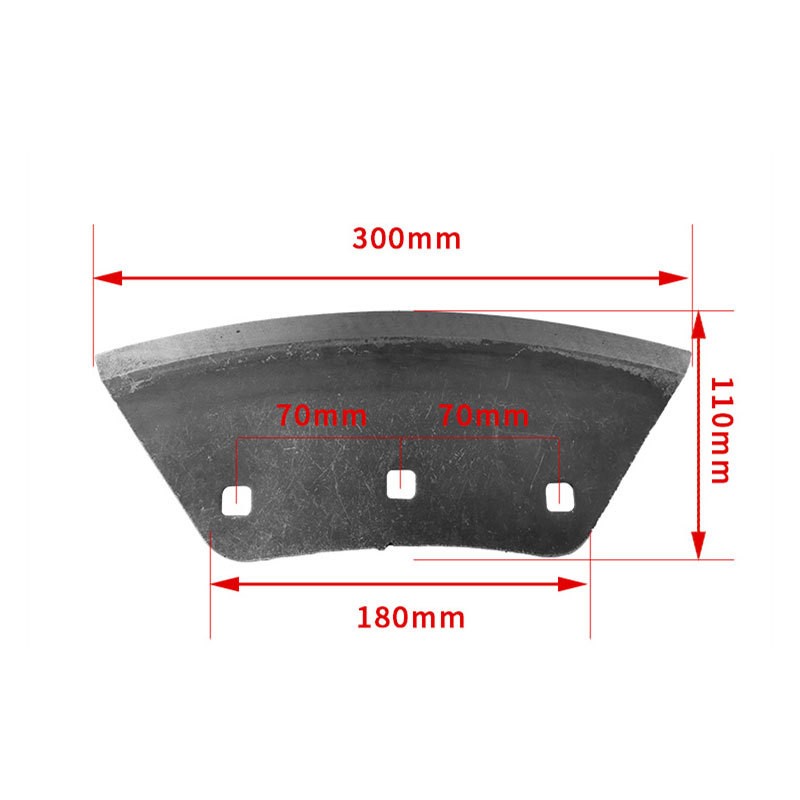

Working elements: these are, first of all, hammers, coronal or shock elements. Their wear depends on the processed material and the intensity of work. Wanted hammers lead to a decrease in performance, and in some cases - to breakdowns.

The details of the shafts and bearings: the shafts on which the hammers are attached, and the bearings that provide rotation are key nodes that require constant attention. Bearing wear can lead to vibration, noise and, ultimately, to breakdown.

Cabinet elements: these include parts that form the crusher body - base, cover, sieve. These elements are often damaged in case of non-compliance with the rules of work or due to abrasive properties of the material.

Electronic components: modern crushers are equipped with electric drives, control systems. These parts are also subject to wear and breakdowns.

How to choose quality spare parts?

The acquisition of spare parts is a crucial moment. It is necessary to focus on the manufacturer of the crusher in order to ensure compatibility. Original spare parts guarantee reliability and durability, but can be more expensive. Alternative options offered by suppliers can be acceptable in price, but require a careful study of their characteristics. An important factor is also the reputation of the seller and guarantees for the spare parts provided.

Preventive maintenance and extension of the service life

Regular maintenance is the key to a long life of a crusher. Preventive examinations allow you to identify worn parts at an early stage, prevent breakdowns and minimize downtime. This, in turn, helps to reduce the costs of repair and increase overall performance. Constant adherence to the recommendations of the manufacturer regarding operation and maintenance can significantly extend the service life of the crusher.