Spare parts for the crusher

Crushes are indispensable assistants in a variety of industries, from mining to waste processing. Like any complex equipment, crushers require regular maintenance and replacement of worn parts. The right choice of spare parts is the key to the uninterrupted and efficient operation of the entire mechanism.

What spare parts most often require replacement?

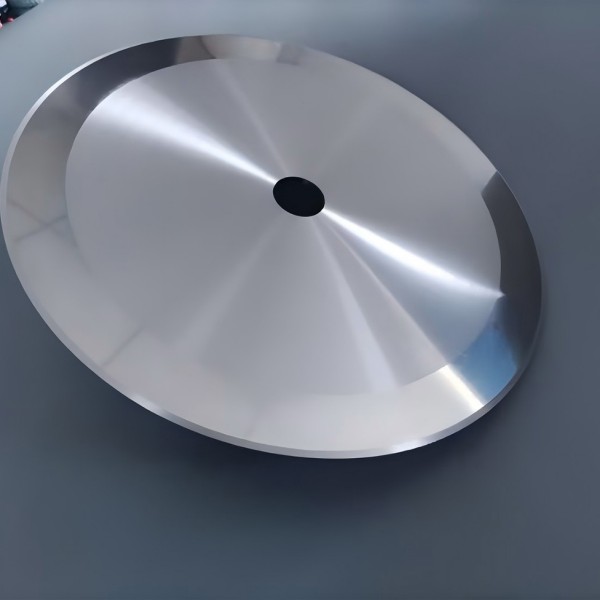

Most often, those details that are subject to maximum wear are changing. These are, first of all, hammers and jaws of crushers. Hams, in contact with the processed material, wear out especially intensively, requiring periodic replacement. The jaws that perform the task of crushing are also susceptible to wear, and their resource depends on the nature of the processed material. In addition, bearings, shafts and other elements wear out the movement and support of the mechanism. The belts and other transmission elements are no less important if the crusher is equipped with an engine.

The choice of quality spare parts is the key to a long crusher service

When choosing spare parts for a crusher, it is extremely important to give preference to trusted manufacturers. Fakes may not only not fulfill their task, but also harm the mechanism itself, causing additional breakdowns. Pay attention to the quality of the materials from which the spare part is made. Sometimes the higher price of the spare part justifies itself for a long service life and reliability. Do not save on spare parts, because this can lead to more serious and expensive problems in the future. Consultation with experienced specialists will help make the right choice.

How to extend the life of spare parts?

To extend the life of the spare parts, it is important to observe the rules of operation of the crusher. The correct selection of operating modes, control over the load, as well as timely lubrication of the nodes will help extend the life of spare parts. Regular maintenance, including diagnosis and replacement of worn parts, is important for uninterrupted work and safety. Do not forget to pay attention to the condition of all elements to identify possible problems at an early stage. This will help to avoid unexpected breakdowns and maintain the efficiency of your crusher for many years.