Forms for potassium machines

Forms for potassium machines are indispensable assistants in metalworking. They set the desired form of metal workpieces, allowing you to create parts with specified geometric parameters. Imagine how complex structures are born from a flat sheet of metal - such as airplane wings, furniture elements or cars. Without special forms like casts, it would be simply impossible.

Varieties of forms and their application

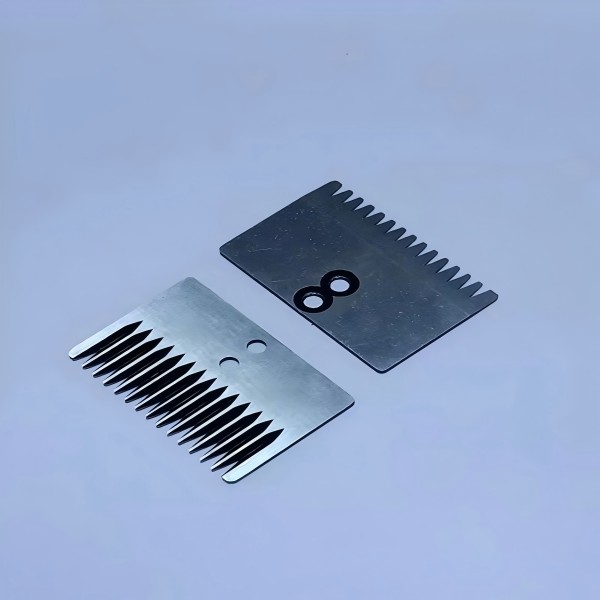

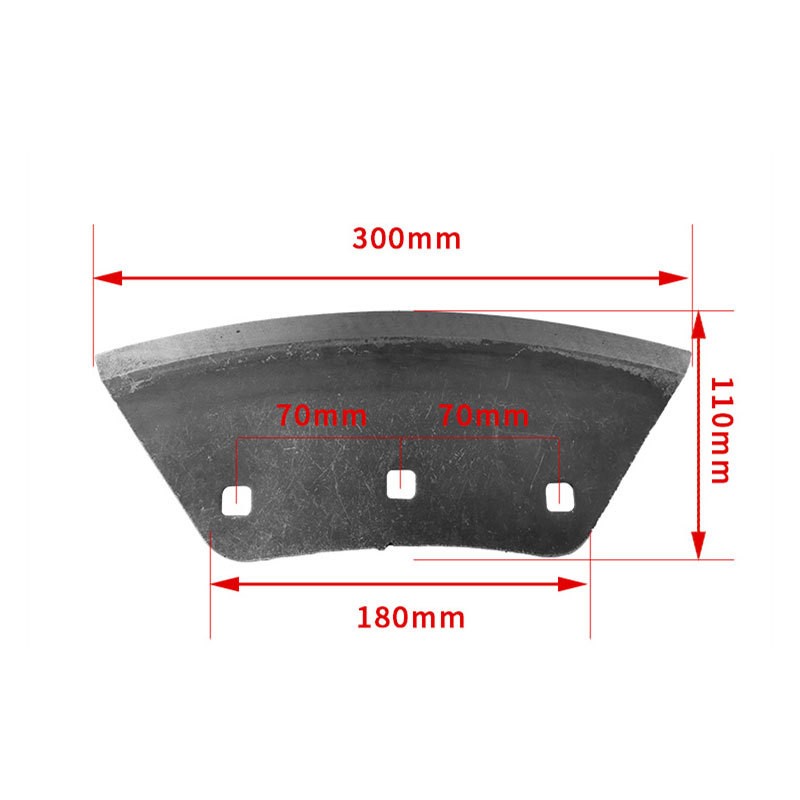

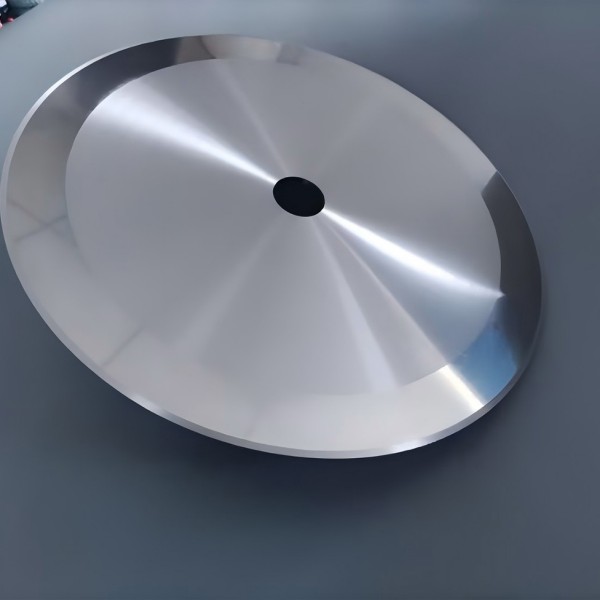

There are many shapes for gy what height machines that differ in material, design and manufacturing method. Some of them are simple, others are complex, with many bends and transitions. For example, to create light details requiring high accuracy, instrumental steel forms can be used. And for less critical details - forms of special alloys, which are relatively cheaper in production. It is important to understand that the form should accurately correspond to the required bend and sizes of the part. Errors in the form will inevitably lead to problems with the quality of the finished product. Forms also differ in the complexity of the profile. Simple forms are used for the same type of bends, and complex, multi -stage - to create more complex, curly details.

Selection of forms depending on tasks

When choosing forms for gypical machines, it is necessary to take into account many factors. This is the material of the workpiece, and the required accuracy of the bend, and the expected production volumes. Forms made using quick prototyping may be suitable for small circulations. For large volumes of production - forms made by more accurate methods. It is also important to think over the strength of the shape: it should withstand significant loads during the operation of the machine without deforming. A poor -quality form can lead to expensive breakdowns or even accidents.

Forms care and their durability

Proper care is the key to a long form of forms. Regular lubrication, cleaning from adhering metal particles and a periodic inspection for damage will help extend their service life. The wear of the forms is inevitable, but competent operation and timely replacement will help maintain high quality processing and save on costs. The breakdown of forms can significantly complicate the production process and lead to unplanned stops. Therefore, it is important to pay attention to the state of forms and replace them in a timely manner.