Steel of the knife guillotine

Guillotin knives are indispensable tools in various industries, from paper to cutting metals. Their effectiveness directly depends on the quality of the steel from which they are made. Let's talk about what makes this steel so important.

The choice of suitable steel: strength and durability

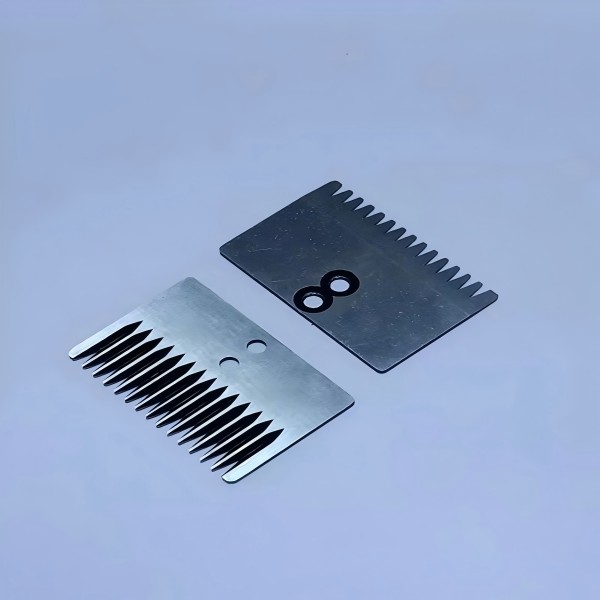

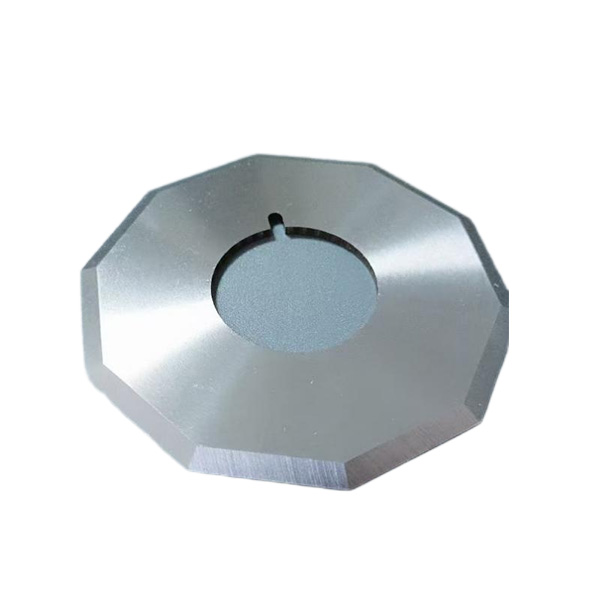

For knives, guillotine requires steel, which has high strength and resistance to wear. Imagine a knife that constantly cuts thick sheets of material - it should be incredibly strong so as not to deform and not break after numerous work cycles. Different brands of steels differ in their properties. For example, some species have become more resistant to corrosion, which is especially important in conditions of high humidity or contact with chemicals. Another steel can be excellently kept sharpening, providing an even and clean slice. The choice of a certain type of steel depends on a specific task - if these are thin sheets of paper, then steel with less hardness will be sufficient, but if we are talking about super -strength metals, then the steel should be as strong and wear -resistant as possible.

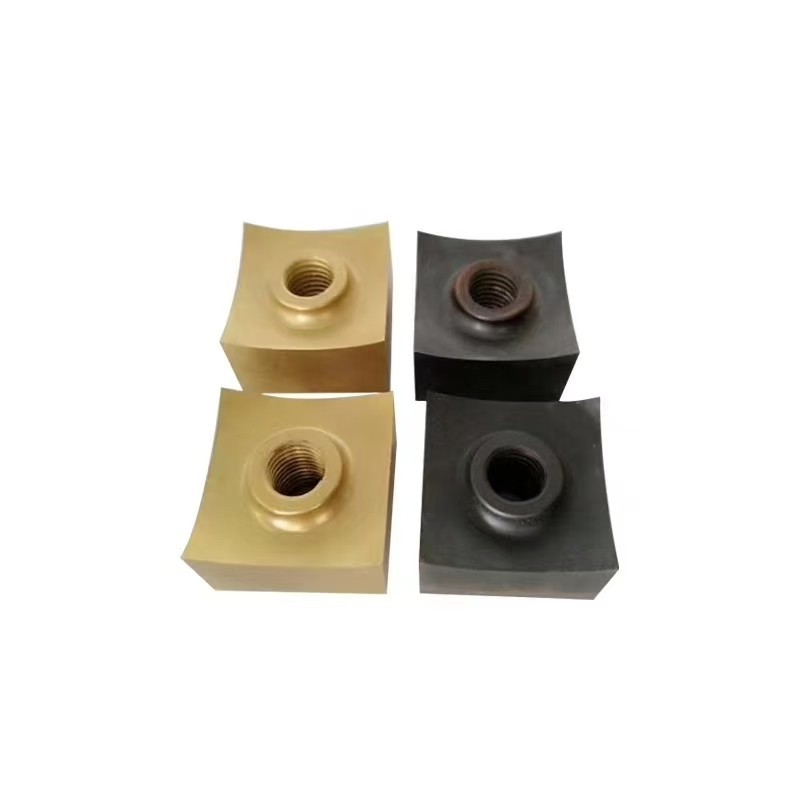

From hardened steel to special composition

Hardening is an important process of steel processing for knives. It allows you to increase strength and hardness, which is critical of the long -term tool for the tool. But this is not the only factor. The composition of steel also plays a key role. Special alloying elements can be added to it, which add additional properties, for example, resistance to corrosion or increased impact. It is all similar to how cooks select spices to prepare a delicious dish - different steels compounds give a different tasting gamut of the tool, making it ideal for specific work.

Test for strength and operational characteristics

Before the knife, the guillotine goes to work, it is subjected to numerous tests. This allows you to make sure that steel and its characteristics meet all the necessary requirements. These tests, as a rule, include checking the strength for bending, cut and resistance to wear. Only after the successful passage of these tests, the guillotine knife is ready to work and can guarantee a qualitative result. And, of course, manufacturers monitor regular maintenance and sharpening of knives in order to maintain them in perfect working condition, ensuring maximum efficiency and safety.