Crusher

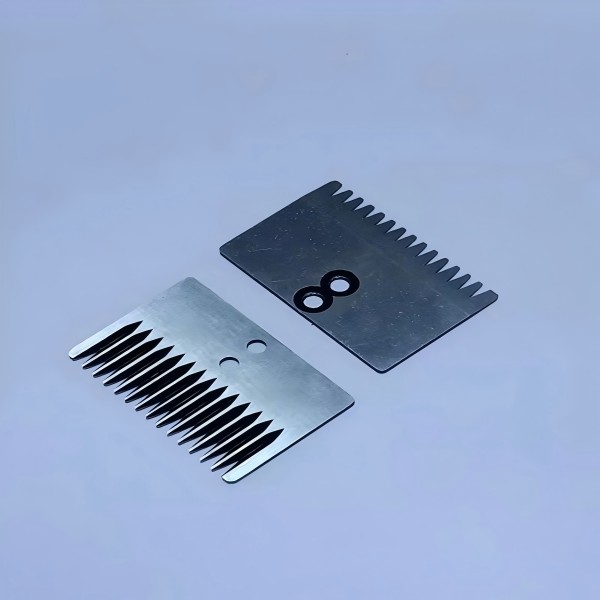

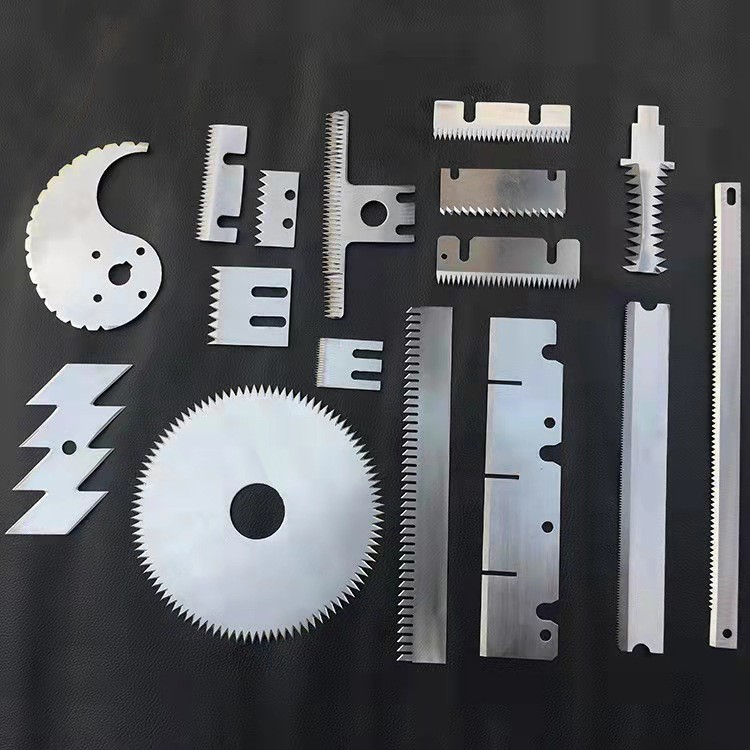

The crusher knives are not just pieces of metal. These are key working tools on which the effectiveness of the entire crushing process depends. The quality of the steel from which they are manufactured directly affects the service life, performance and safety of the equipment. Consider what you need to know about steel for crusher knives.

The choice of steel is not an easy task

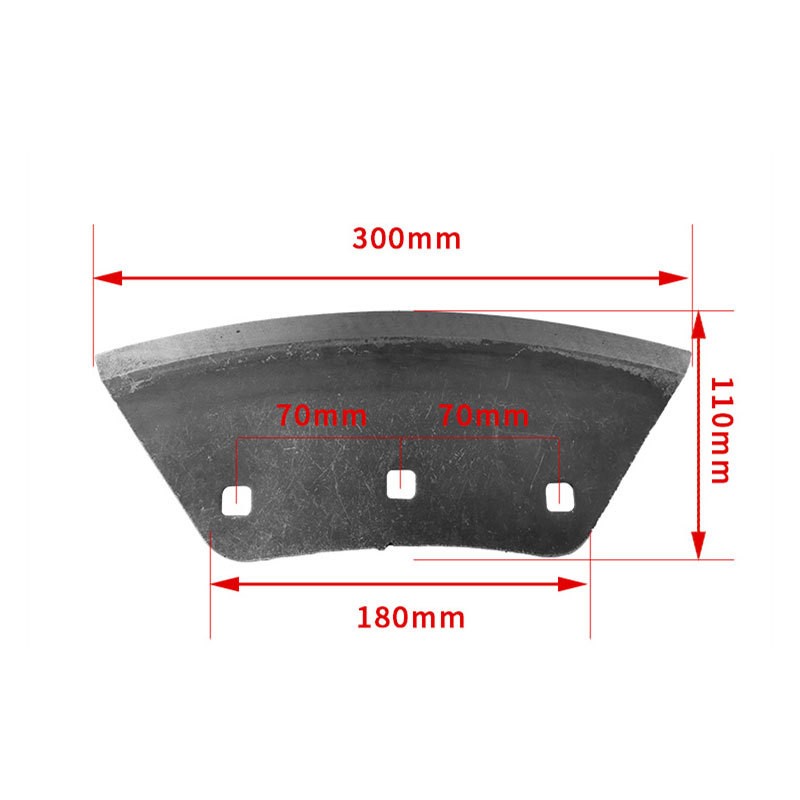

The choice of suitable steel for knives of the crusher is a painstaking work, comparable to the choice of the right one? Gloves? For a difficult task. Different types of materials to be crushed (grain, stone, scrap metal) require different steel composition. Knives for grinding hard rocks should be made of more durable and wear -resistant steel than knives for soft materials. It is important to consider such characteristics as hardness, shock viscosity, corrosion resistance and resistance to wear. Metallurgists select the optimal composition, taking into account the specifics of the load and working conditions of the crusher.

Features and advantages of various types of steels

There are various brands of steels, each with its own unique characteristics. For example, high -carbon steel has high hardness, which provides a long service life, but they can be fragile. Located steels, with the addition of various alloying elements, usually have better compatibility of hardness and viscosity. Some steel are specially designed for resistance to wear, others for better resistance to corrosion. The choice of a particular brand depends on the type of material to be crushed, and specific operating conditions of the crusher. Not only properties are taken into account, but also the cost of the material.

Manufacturing technology and impact on quality

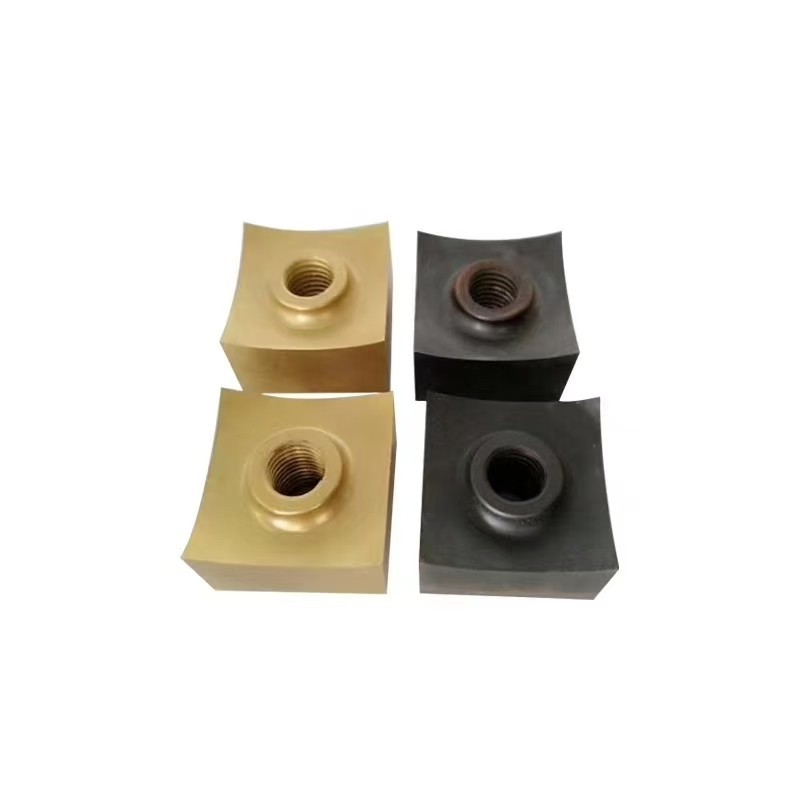

The quality of steel is not only its chemical composition, but also the technology for its processing. The manufacturing process of the crusher knives includes several stages, starting with swimming and processing, ending with hardening and subsequent surface treatment. The quality of heat treatment, for example, hardening, directly affects the hardness and wear resistance of steel. Properly manufactured knives provide more efficient operation of the crusher, reduce repair costs and, ultimately, increase economic efficiency. Sharpening methods that affect the accuracy and life of the knives are also important.