Rollers for straightening for steel smelting

The process of steel smelting is a complex and important stage in the metallurgical industry. To obtain high -quality steel, which is used in various fields - from construction to car manufactured, careful observance of the technology is required. One of the key elements of this process is rollers for straightening. Imagine a hot, plastic metal that needs to be brought into a perfectly even state. It is here that these inconspicuous, but extremely important assistants come to the rescue.

The purpose and principle of the work of the film

Rollers for straightening are, in fact, special rollers that pass red blanks through themselves. They do not just miss them, they controlled on the shape and size of steel, giving it the desired even surface and geometry. Imagine that you are trying to smooth a crumpled sheet of paper - the videos work in about the same way, but with much greater strength and temperature. Due to the special profile and pressure, the metal is straightened, getting rid of bends and bumps, which subsequently affects the quality of the final product.

The importance of rollers in the process

The straightening of steel with the help of rollers is not just a formality. This is a critical stage that affects the strength and durability of finished products. The bumps and bends remaining after smelting can lead to cracking, deformation or reducing the strength of the finished steel. Thus, the rollers provide not only an even surface, but also guarantee the reliability and durability of the final product. They, like hidden masters, monitor every step so that steel acquires the desired characteristics.

A variety of features of rollers

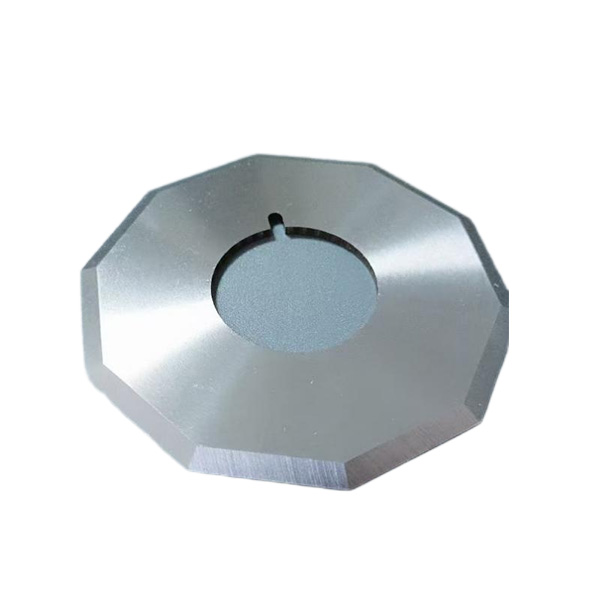

There are many structures of rollers, each of which is adapted to a certain type of steel and the specifics of production. From the diameter and material of the manufacture of rollers to the cooling system - each parameter is carefully worked out to achieve the optimal result. The presence of various types of rollers allows manufacturers to adapt to the needs of different industries where steel is used. Different rollers provide a different degree of pressure and speed, so the process is configured for the needs of a particular production.