Knives of a single shredder: reliable assistants in work

The knives of a one chopper is an indispensable tool in various industries, from the food industry to waste processing. They play a key role in the grinding process, providing high performance and quality of the final product. But how are these knives arranged, and what factors affect their effectiveness? Let's figure it out.

Construction and materials of knives

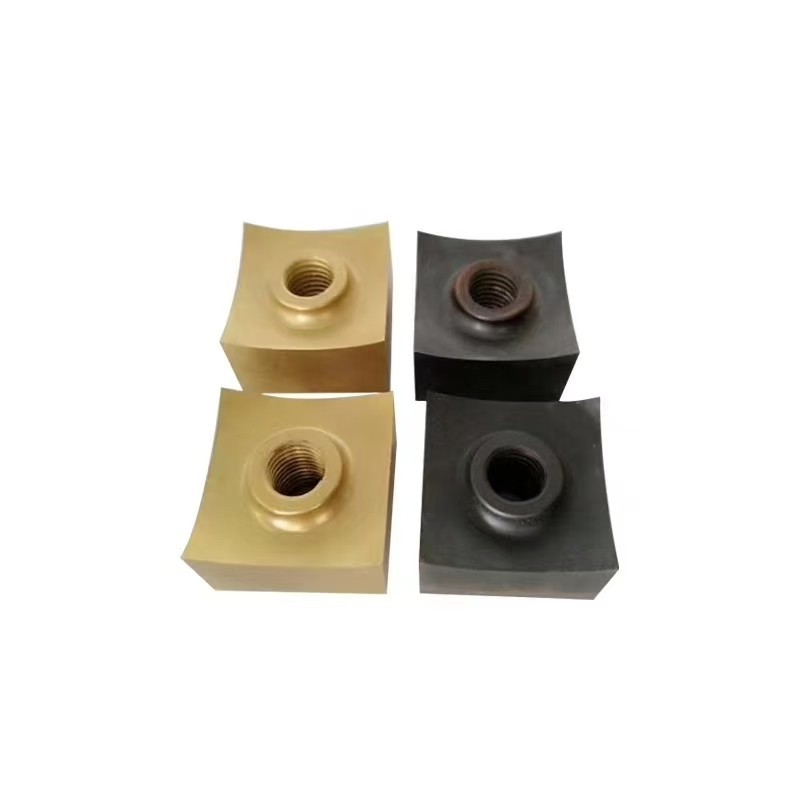

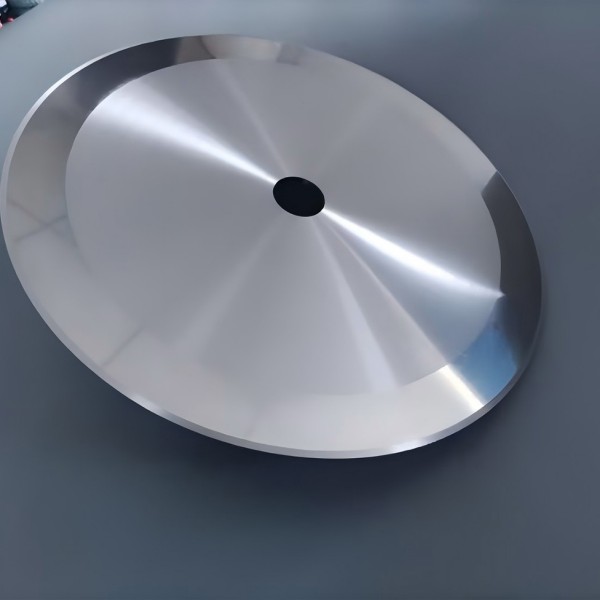

The chopper knives are not just pieces. They are created with the exact calculation in order to effectively cope with the task of crushing. Often there are knives made of high -strength steel that can withstand high loads and sharp blows when working with hard materials. The shape of the knives can vary depending on the specific model of the grinder and the desired grinding result. Sometimes there are knives with teeth or sharp edges for more effective and uniform grinding. The quality of steel and its heat treatment directly affect the life of the knife and its ability to maintain sharpness for a long time.

Factors affecting the choice of knives

The choice of suitable knives depends on several factors. It is important to consider the type of material that will be crushed. For soft products, such as vegetables or fruits, knives with lower strength can be suitable, and for solid and hard materials such as bones or wood, knives made of more durable steel are required. It is also necessary to take into account the power of the grinder itself, since too weak the engine cannot cope with the task of grinding hard material with high strength knives. The choice of product particles also affects the choice. The smaller you need to grind the material, the more sharp and often located knives you need.

Care and replacement of knives

In order for the knives of a one grinder to serve for a long time and effectively, they need to be properly taken care of. Be sure to follow the manufacturer's instructions for maintenance and cleaning. Regular checking of knives for chips and cracks will allow timely detecting problems and avoiding breakdowns. The blurry knives reduce performance and can harm the equipment. Therefore, periodically, the knives should be sharpened or changed to new ones. Replacing knives is an integral part of the shredder service that allows you to maintain a high level of grinding quality and work safety.