Knives on a crusher-shredder with surfacing surfacing

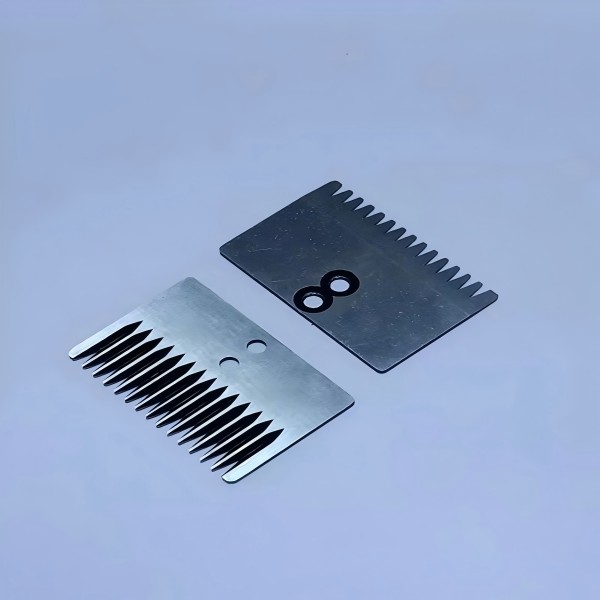

Knives on crushers-shredders equipped with a surfacing with solid alloys are special tools that play a key role in the effective processing of various materials. Imagine powerful mechanisms that are easy to tear, crushed and process various waste, metals or polymers. In these processes, the knives perform a difficult task, undergoing wear and constant pressure. The surfacing of carbide materials on knives is how to put on armor on them so that they serve longer and more efficiently cope with their work.

Advantages of carbide surfacing

The surfacing of the carblinks on the knives of the crusher-shredder provides them with high wear resistance. The solid alloys from which these surfaces are made are significantly superior in terms of hardness and resistance to wear ordinary metals. This means that knives with surfacing withstand more work cycles, are less susceptible to deformation and breakdown. As a result, this leads to a significant decrease in the cost of maintenance and replacement of knives, as well as to increase the performance of the entire carcass of the spacecraft. So, for example, the processing of more rigid materials, such as metals or plastic, becomes possible.

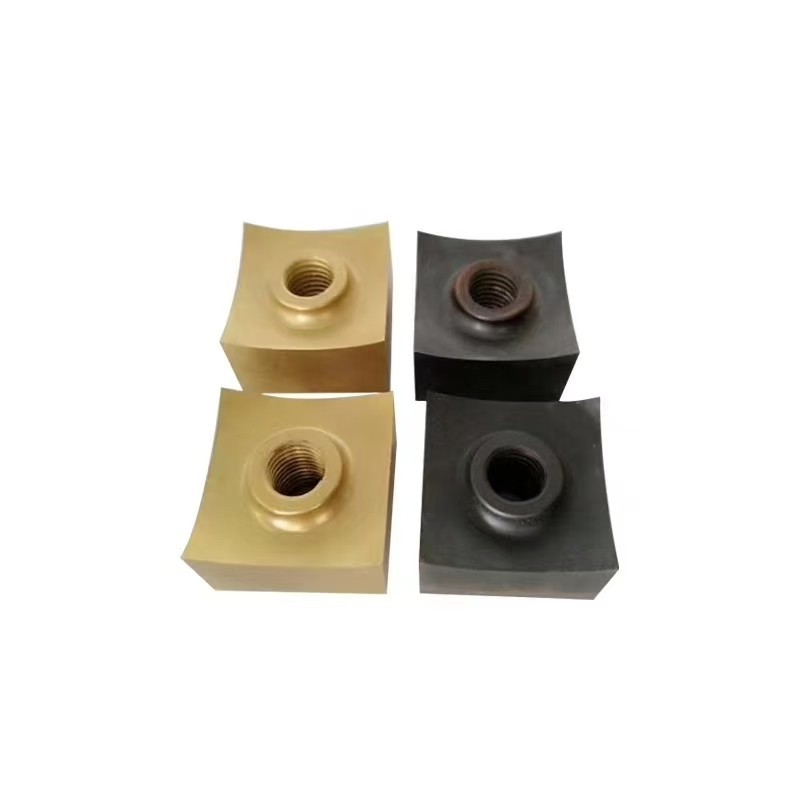

How is the correct survey material selected?

The choice of specific carbide material for surfacing depends on the specifics of the processed material. For working with soft polymers, one alloy is suitable, and the other is suitable for processing hard metals. Specialists take into account all the factors: the type of materials processed, wear speed, operating mode of the crusher-cheater and much more. This allows you to choose the optimal surfacing option that maximally increases the efficiency and life of the knives. As a result, each case is individual.

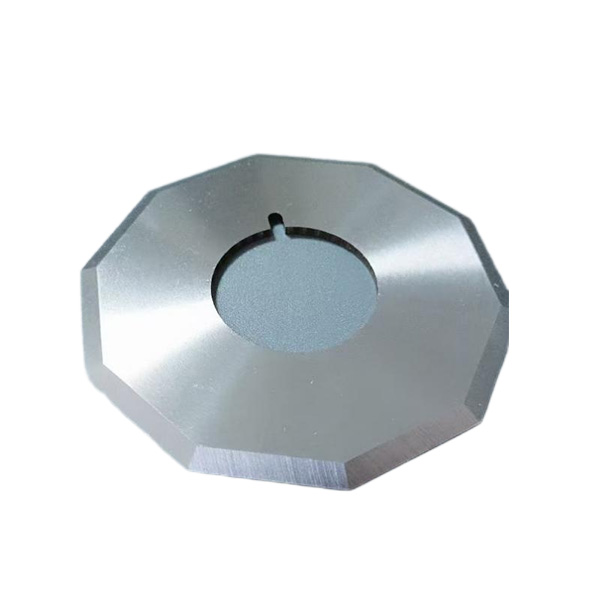

Care and operation of knives

Proper care of knives with surfacing with carbide materials plays an important role in their long -term work. Regular inspection for damage, compliance with the rules of operation of the crusher, as well as timely maintenance of mechanisms - all this contributes to durability and high performance. This allows you to significantly reduce the costs of repair and maintenance, as well as maintain a high level of quality of operation of the entire crushing installation. Remember that the effectiveness of the work of all technology depends on competent care.