Knives on a drill

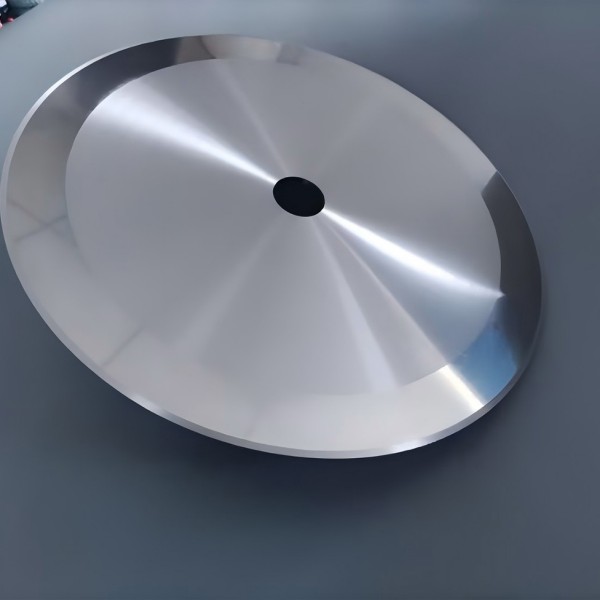

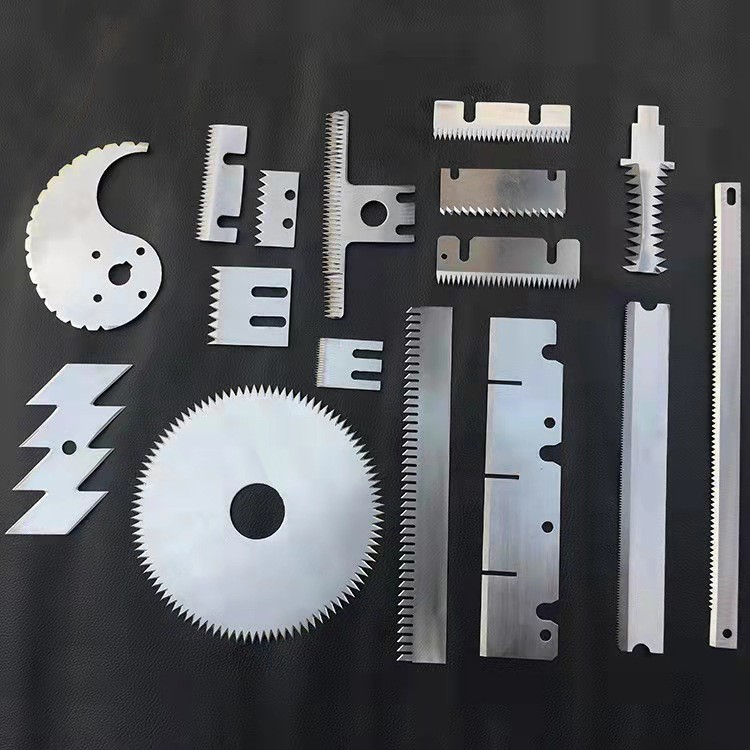

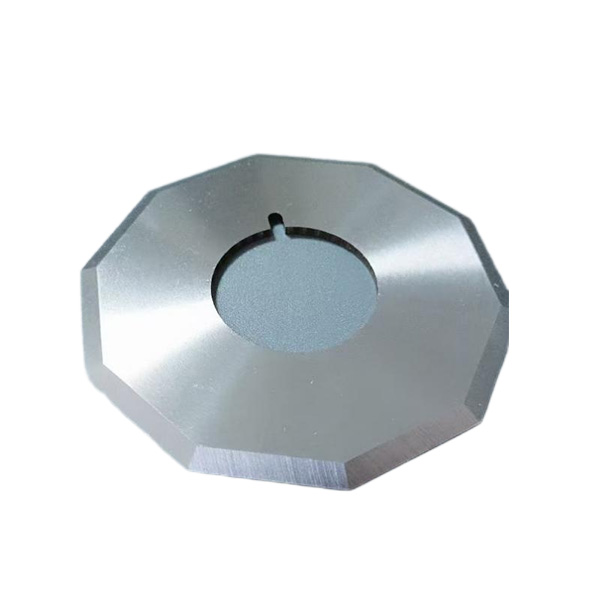

Tough knives on a drill is a special type of tools used in construction and other industries. They differ from ordinary knives with their design and the ability to perform specific tasks. In fact, these are knives attached to the rotating bunt (bora) on which the teeth are located. Imagine small, but very sharp blades that cut, cut or cut off the material during rotation.

The principle of operation and application

The basic principle of operation of such knives is their combination with the rotational movement of the drill. The gear surface of the drill and sharp blades of the knives create a powerful tool for different tasks. For example, they are indispensable for sawing, cutting, cutting wood, stone, plastic or even some metals. Often they are used in the construction, manufacture of furniture, production of various parts, etc. It is important to note that the choice of a particular type of knife on a rivet drill depends on the material that must be processed, and on the required accuracy of the work.

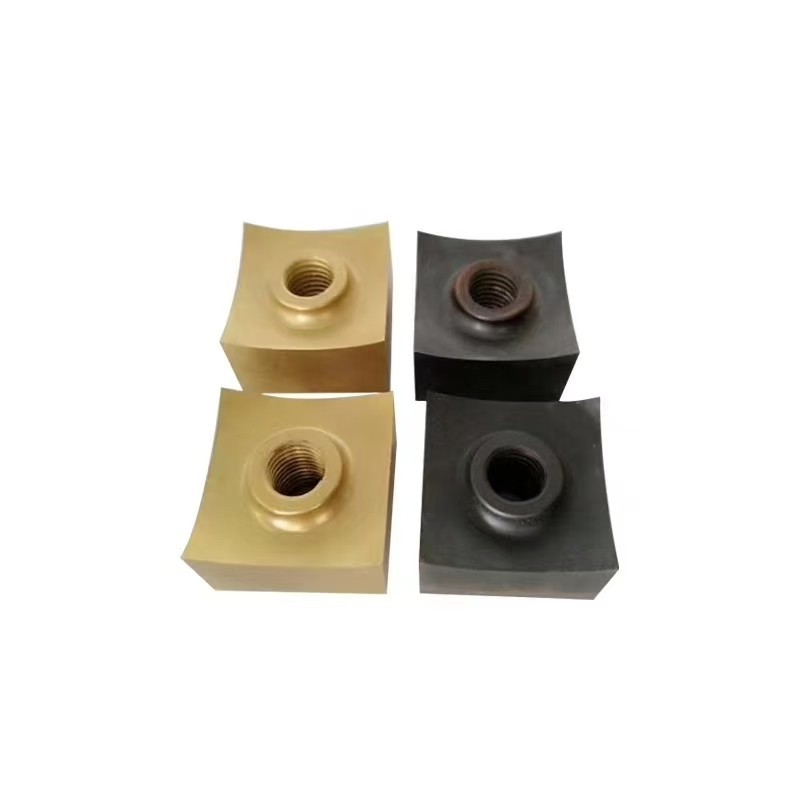

Varieties and choice of knives

Different types of knives on a toothed drill differ in the material of the manufacture of blades, the angle of sharpening and the shape of the teeth. For example, for soft wood, knives with softer blades are suitable, and for more solid materials - knives with more durable and sharp blades. The choice of knives also depends on which teeth are installed on the drill. It is important to make sure that the knife is ideal for a certain drill and material. An incorrectly selected knife can damage the tool or material, as well as not give the expected result. Therefore, when choosing a knife, you need to pay attention to the recommendations of the manufacturer and the experience of use.

Safety during work

Working with knives on a tough drill requires compliance with safety measures. It is necessary to use personal protective equipment, such as protective glasses and gloves. Be sure to check the condition of the knives and drill before starting work in order to avoid breakdowns during operation. Also, work in a well -lit and ventilated room. Following these simple rules, you can do the work as safe as possible and get the best result. Do not forget that compliance with precautions is the key to successful and safe work.