Knives for a tool for the production of wood chips

Knives are an indispensable tool for the production of wood chips. They, like small, but very important soldiers, fulfill the main task - turning a whole piece of wood into valuable material. Like any army, knives for machine tools have their own characteristics that determine their effectiveness and durability. Without high -quality knives, the process of producing chips becomes slow, complex and, most importantly, less productive. Therefore, the choice of knives is not just a technical moment, but a key factor in the success of any production.

Knife choice: not only quantity, but also quality

It is important to understand that the quality of the knives directly affects the quality of the final product. Sharp, properly sharpened knives allow you to evenly and quickly split the wood, which leads to a flat, high -quality and predictable result. Knives with stupid edges will work for a long time and hard, as a result of which the quality of the chips suffers and the time of work increases. The number of knives also matters, but no less important is how they are located and how sharp they are. It is necessary to periodically check their condition and, if necessary, sharpen. This will maintain constant speed and efficiency of the process.

Knife care - the key to long and uninterrupted work

Like any tools, knives for machines require careful handling and care. Regular cleaning of wood sawdust and chips is a guarantee of their long service. Polluted knives will die faster, which will affect the speed of work and the quality of the final product. No need to neglect a simple, but important stage - cleaning. It is also worth ensuring that the knives are stored in suitable conditions, protected from moisture and dust. Sharpening of knives is another important element of care that will provide their long service and efficiency.

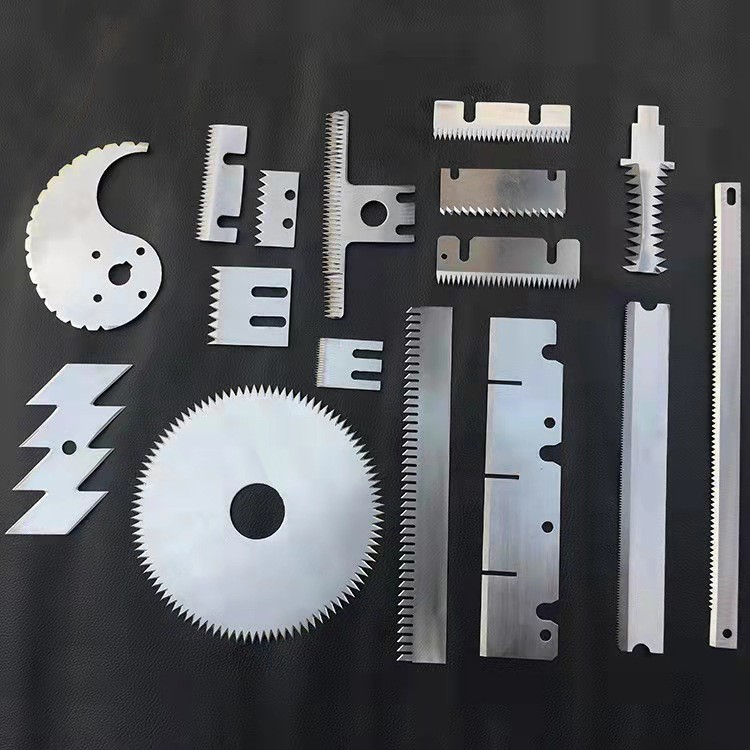

Types of knives and their use

The variety of tasks solved by machines for the production of wood chips also dictates a variety of types of knives. Some knives are designed for processing soft wood, others for harder. It is important to select knives suitable for the material used. The right choice will achieve the perfect result, minimize costs and ensure high process productivity. Therefore, it is worth paying attention to the recommendations of the machine manufacturer and use only recommended knives. Knowing the species and their purpose is the way to optimal work of the machine and obtaining maximum benefits from production.