Low -speed crushers knives

Low -speed crushers are indispensable assistants in various fields of activity, from agricultural waste processing to construction waste processing. The key element of such devices is knives. Their choice and quality directly affect the effectiveness and durability of the entire crusher. Consider the main aspects that must be taken into account when choosing knives for low -speed crushers.

Knife materials: strength and wear resistance

The reliability of the knives is based on the materials used. For low -speed crushers, where the main load is not as high as in high -speed analogues, strength and resistance to wear are important. Most often, steels with a high content of chromium, tungsten or other alloying elements are used. These metals provide the necessary hardness and wear resistance, allowing the knives to withstand repeating loads and not collapse when contacting various materials. It is important to pay attention to the brands of steel and the recommendations of the manufacturer in order to ensure the optimal operation of the tool.

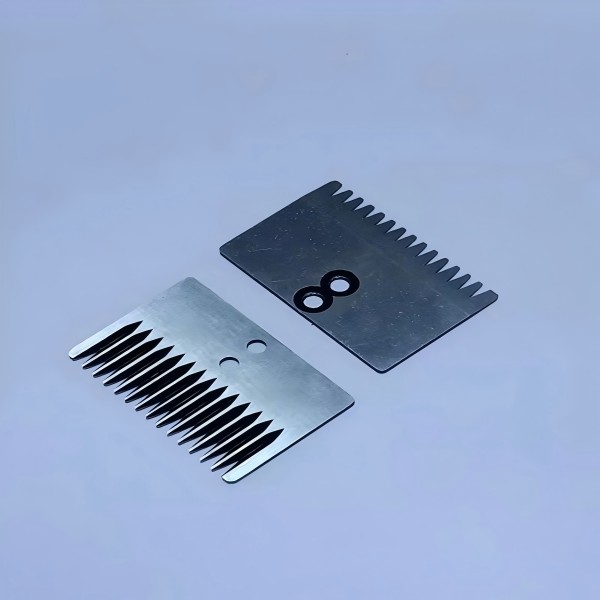

Geometry and shape of knives: the effectiveness of crushing

The shape and geometry of knives play a decisive role in the effectiveness of the crushing process. Various materials require a specific approach. For example, knives with more smooth lines are suitable for soft waste, while for more solid materials you need more acute and cutting edges. Modern knives often have special profiles that optimize the crushing process, reducing wear and increasing the productivity of the crusher. It is necessary to take into account the features of the processed material when choosing a knife tool.

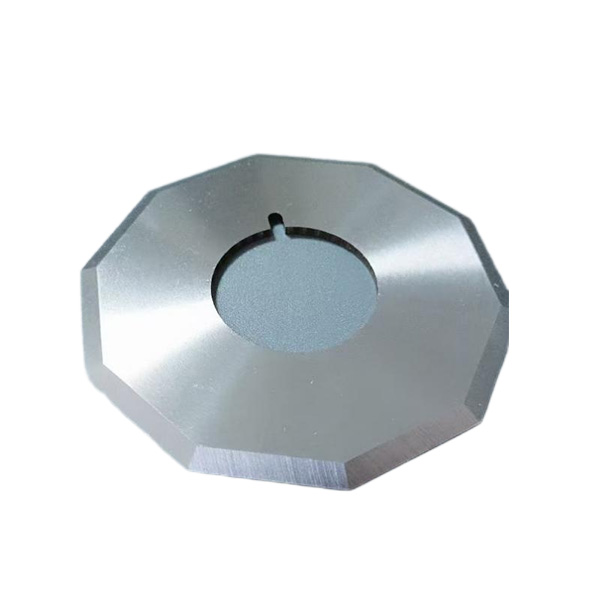

Installation and maintenance of knives: ensuring safety and durability

The correct installation of knives is the key to safe and durable operation of the crusher. Failure to comply with instructions can lead to breakdowns and injuries. It is necessary to carefully follow the manufacturer’s instructions for the installation, use the recommended fasteners and regularly check the condition of the knives. Regular maintenance, including sharpening or replacing worn knives, significantly increases the service life of the entire crusher and prevents possible emergency situations. Simply put, timely care for knives is the key to success.