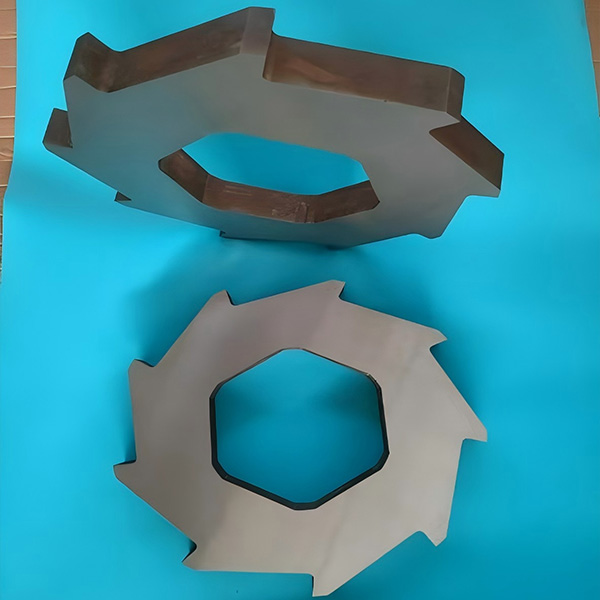

Hammer crusher knives

Hammer crusher knives are a key element of this important equipment. Imagine a huge hammer that waves the material with incredible force. Now imagine that this hammer has sharp, strong knives. It is these knives that provide effective grinding of various materials: from grain to rocks. Is knives a kind of teeth? crushers that work without lingering hands to do their work efficiently.

The choice of suitable knives: not only form, but also material

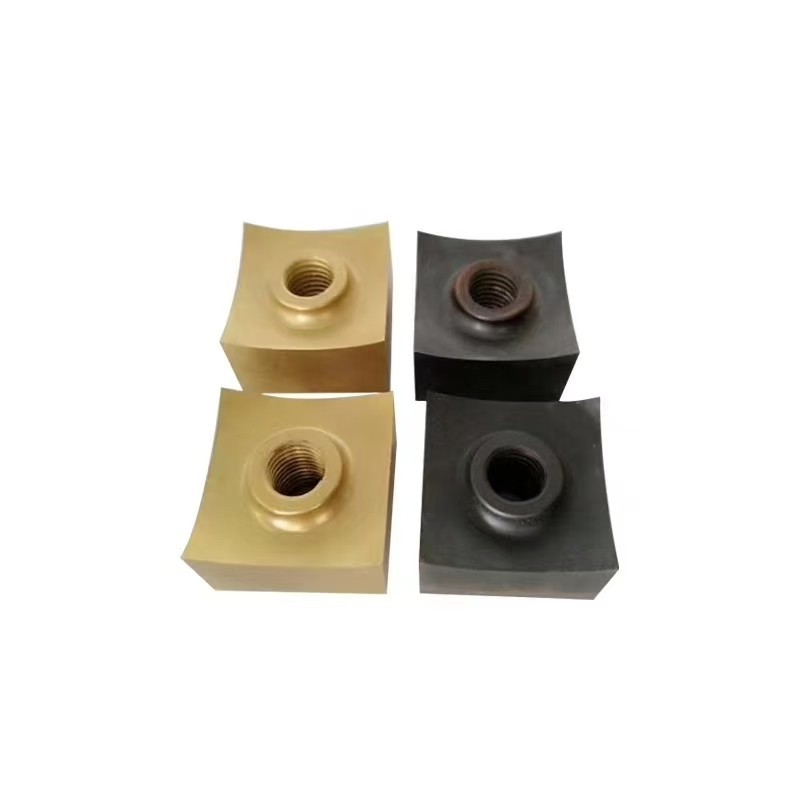

The choice of knives for a hammer crusher is a task that requires an attentive approach. Not all knives are equally effective. It is important to consider not only the shape of the knife, but also the material from which it is made. For example, for grinding soft materials, such as grain, knives from a softer alloy are suitable. For more rigid materials, like stones, we need knives made of more durable steel that can withstand high loads. The quality of steel directly affects the durability of knives and, accordingly, the economic efficiency of the crusher. It is also important to monitor the geometric parameters of knives, for example, the thickness and angle of sharpening. The right knife is the key to the long and uninterrupted operation of the crusher.

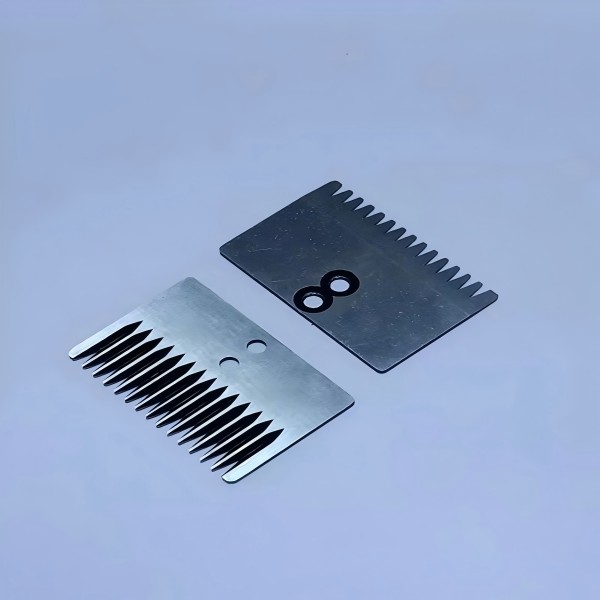

Knife care is the key to their durability

Knives for a hammer crusher, like any other equipment, need proper care. Regular testing of knife severity is an important stage. Dumb knives not only reduce grinding efficiency, but also increase the load on the crusher, which leads to premature wear. The blunt knives must be sharpened or replaced. It is important to regularly clean the knives from adhering particles of the material. This will allow them to work with maximum efficiency and extend their service life. Competent care will allow you to get the maximum return on your investment in the crusher.

Repair and replacement of knives: when it is necessary

Damaged or worn knives will require repair or replacement. This is not only a matter of effectiveness, but also safety. If the knives have cracked, or their geometry is distorted, it is necessary to take measures to replace them. Do not pull with a replacement or repair, because faulty knives can lead to an accident or breakdown of all equipment. Contact qualified specialists to carry out repair work in order to avoid unnecessary problems and not risk their safety.