Knives for a crusher of plastics buy: how to choose the right tool

The modern world is the world of plastic. But, like any material, plastic needs processing. And here knives for crushers are indispensable. The right choice of knives is the key to the effective and safe operation of your equipment. To understand this issue, let's go through key points.

Knife materials - what to look for?

For a crusher of plastic, knives from various materials are suitable. Most often, high -quality steel is used, the hardness of which guarantees the durability of the tool. It is important to understand that the strength and resistance to wear of knives directly affect the life of the entire crusher and the economic efficiency of its use. Alloy with the addition of special alloying elements can increase corrosion resistance and wear, which is especially important when working with various types of plastics. Also, when choosing, pay attention to the possibility of sharpening or replacing individual knives - this will significantly reduce your expenses in the future.

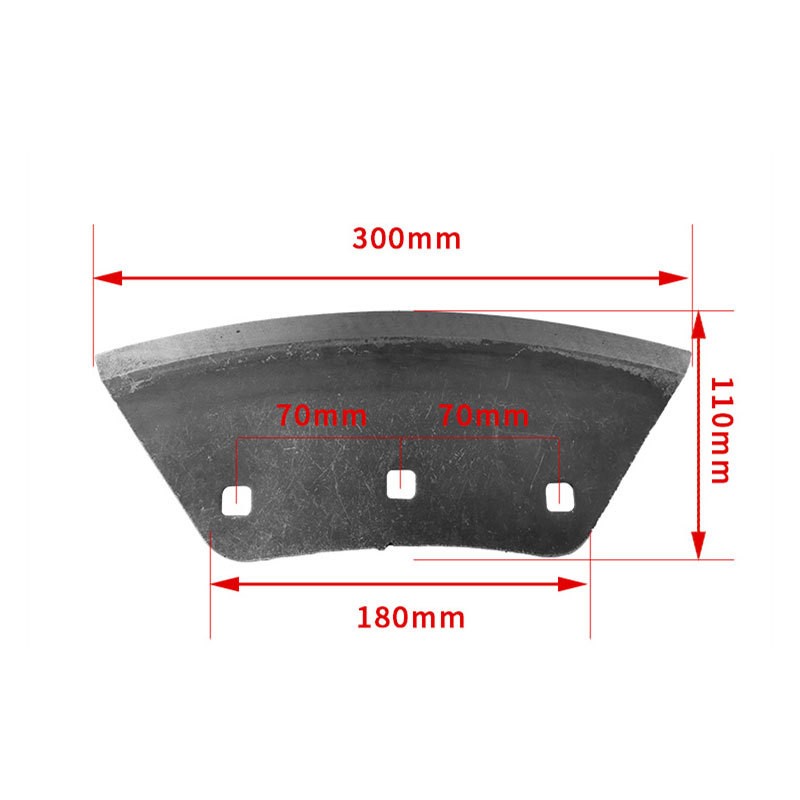

Dimensions and shape - what to consider when choosing?

The size and shape of the knives are critical parameters. They must correspond to a specific model of the crusher. Incorrectly selected in size or shape, knives can lead to a breakdown of the equipment itself or to ineffective crushing. Look for knives that have an optimal shape for effective cutting and grinding of different types of plastics. Pay attention to the width and thickness of the cutting edge. These parameters affect the performance and durability of the knife. The optimal shape of the knives allows you to grind the material as quickly as possible and evenly, which positively affects the quality of the final product.

Safety is above all - how to avoid breakdowns?

When purchasing knives for a crusher, do not forget about safety. Make sure that the selected manufacturer and the knife model meet security standards. Check the presence of protective mechanisms that prevent random injuries during operation. Also, do not neglect the instruction manual. Proper use of knives and compliance with safety regulations is the main factor to avoid breakdowns, injuries and expensive repairs. When choosing, pay attention to the reliability of attaching knives to the shaft - a poor -quality mount can lead to premature wear and breakdown of the entire mechanism.

As a result, the choice of knives for the crusher Plastmass is a responsible step that affects the effectiveness and safety of your work. Compliance with these simple rules will help you make the right choice and get a durable and effective tool.