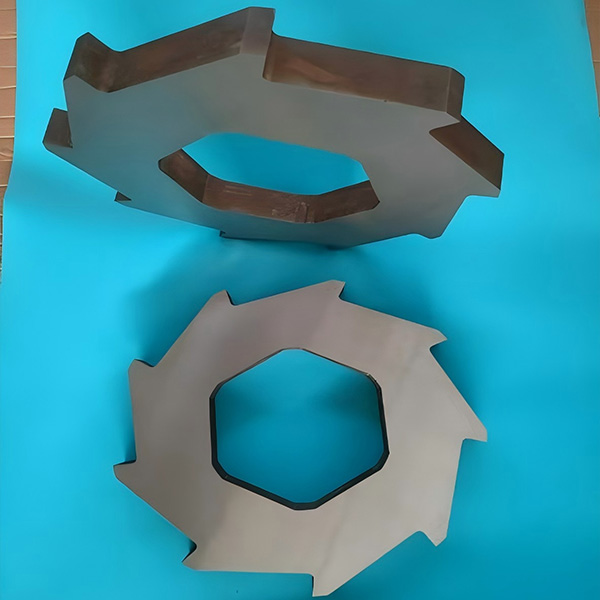

It has a wide range of application in many areas, mainly including the processing of waste mass, metals, wood, paper and other materials. The blades of a one chopper usually consist of a cutting head and blades. The cutting head is the main part of the blade, usually round.

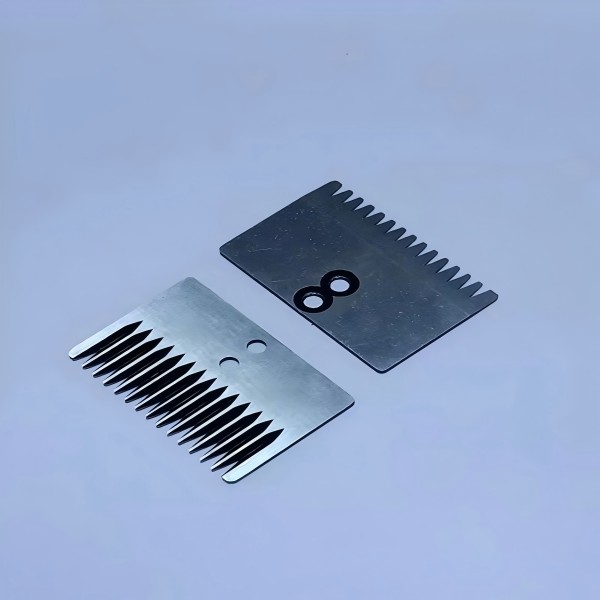

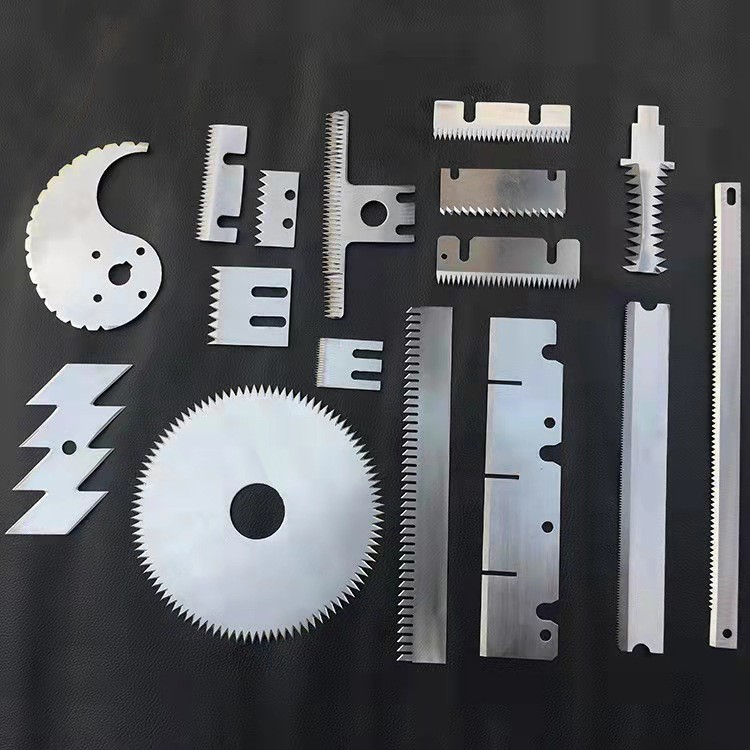

It has a wide range of application in many areas, mainly including the processing of waste mass, metals, wood, paper and other materials. The blades of a one chopper usually consist of a cutting head and blades. The cutting head is the main part of the blade, usually round. It serves to fix and support the blade and is connected to the main shaft of the grinder. The blade is a part that is in direct contact with the crushed material. The usual shape of the blade is hook -shaped and gear. The hook blade has unique advantages when capturing and tearing materials, and the gear blade is suitable for working with materials of higher hardness. The square blades of the one -to -chopper of one are usually made of high -quality materials, such as high -strength alloy steel. After special heat treatment, they have high hardness and wear resistance.

The choice of this material guarantees that the blade will retain acuity and reduce wear during prolonged work, especially when processing scrap metal. Thus, the square blade of a single grinder is used in the processing of plastic scrap. This plays an important role. When processing materials such as metal, wood and paper. Its high efficiency and durability make it key equipment in the processing of resources and environmental protection.