Blades for metallurgy and rental steel

Metallurgy is a real magic that turns ore into strong steel, which are then used to create everything - from bridges to knives. And in this magic, blades play the most important role. These invisible assistants, like small, but powerful tools, help to control and form metal at each stage of production. Imagine a giant machine that twisting and pulling steel - without sharp, strong and wear -resistant blades, this process would be impossible.

Types of blades and their tasks

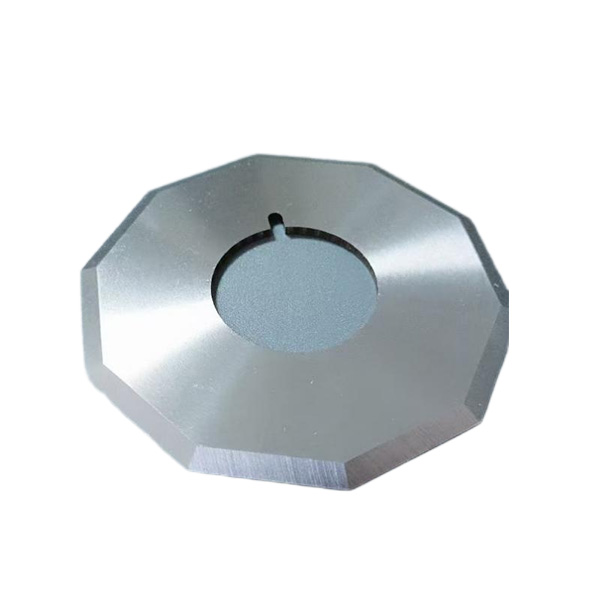

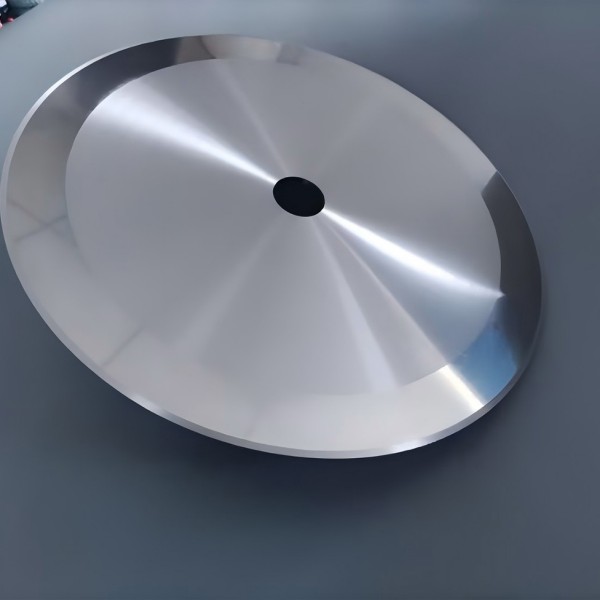

In metallurgical production, different types of blades are used, each with its own specialization. There are blades for cutting, compression, and even for subtle steel formation. To cut the sheet of steel, we need blades with high bending strength to withstand powerful mechanical loads. But when stretching thin steel wires - blades are needed to maintain smoothness and accuracy of size, as when working with incredibly thin fiber. The choice of a particular blade depends on the type of steel and the desired result.

Material embodiment and quality

The quality of blades is the key to successful production. Their durability and effectiveness directly depends on the material from which the blades are made. For high temperature conditions, for example, when smelting steel, blades from special, heat -resistant alloys that are not deformed and do not lose their severity are used. For cold rental, on the contrary, you need special steel, which allows you to cut the thinnest layers of metal without loss of quality. Ultimately, the high quality of the blades is a guarantee of stability and quality of the entire process, from the strength of bridges to the accuracy in the production of small parts.

Technology and future blades

Modern technologies allow you to create blades with unique characteristics. Different methods of hardening and surface processing are used, which significantly increases the life of the blades and increases their accuracy. In the future, we can expect the development of new materials and technologies that will make the blades even more effective and durable. New methods for improving blades will allow metal structures to be even more complex and quality.