Blades for hydraulic boards

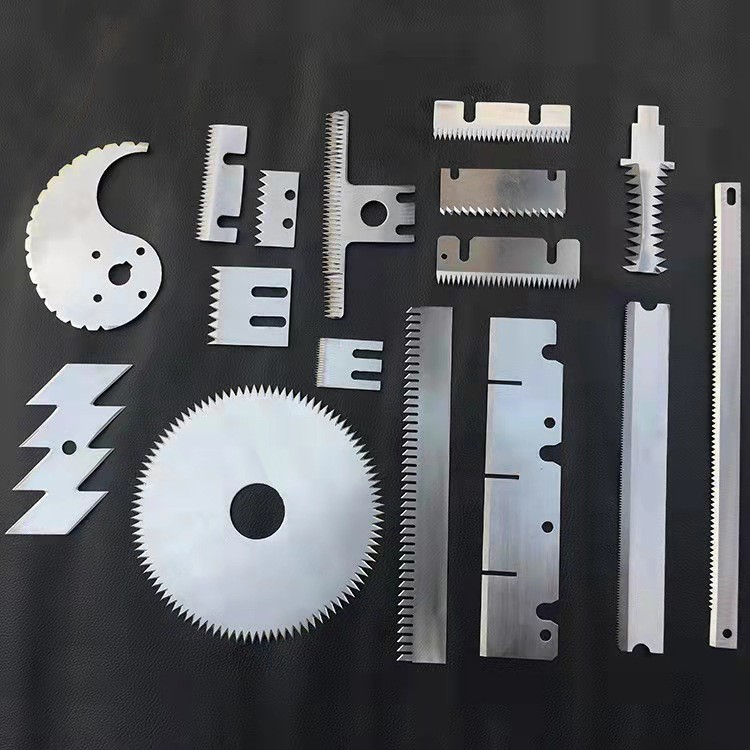

Hydroelectric surveys are indispensable assistants in working with various materials, from metal to plastic. The key element of their effectiveness is, of course, blades. Properly selected and regularly replaced blades guarantee durability and high quality of work. Let's figure out what nuances should be taken into account when choosing them.

Choosing blades on the material

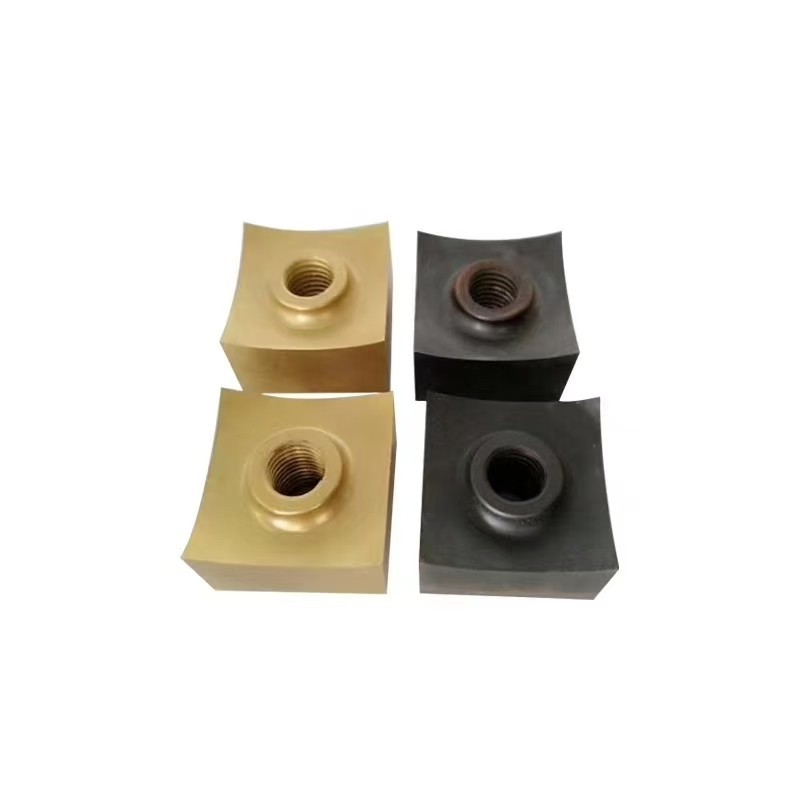

The blades for hydraulicities are made of various materials, and the choice depends on the processed material. For working with thin metal, for example, aluminum, high -quality steel blades are suitable. They provide a smooth and neat cut, minimizing the deformation of the workpiece. If you have to work with a stronger and more thick metal, for example, steel, then it is more optimal to choose blades made of more durable instrumental steel. For plastic and other non -metallic materials, there are also special blades that provide optimal adhesion and incision without damage to the treated surface.

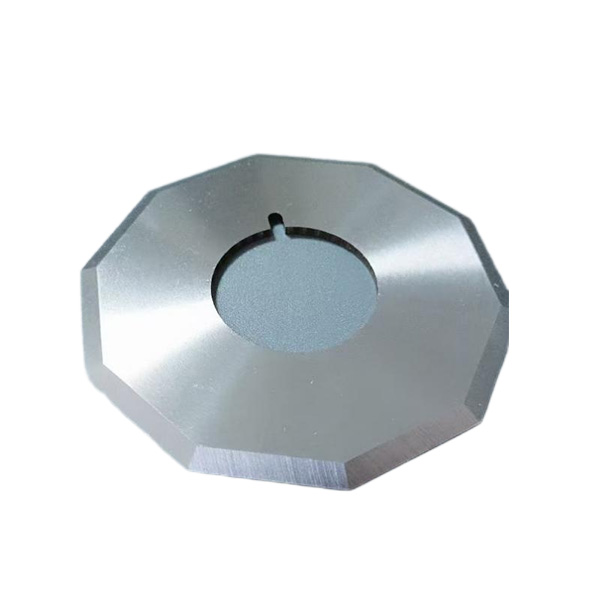

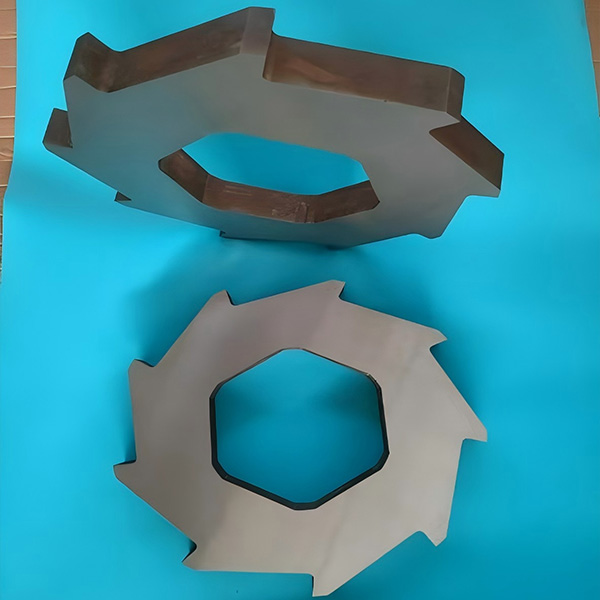

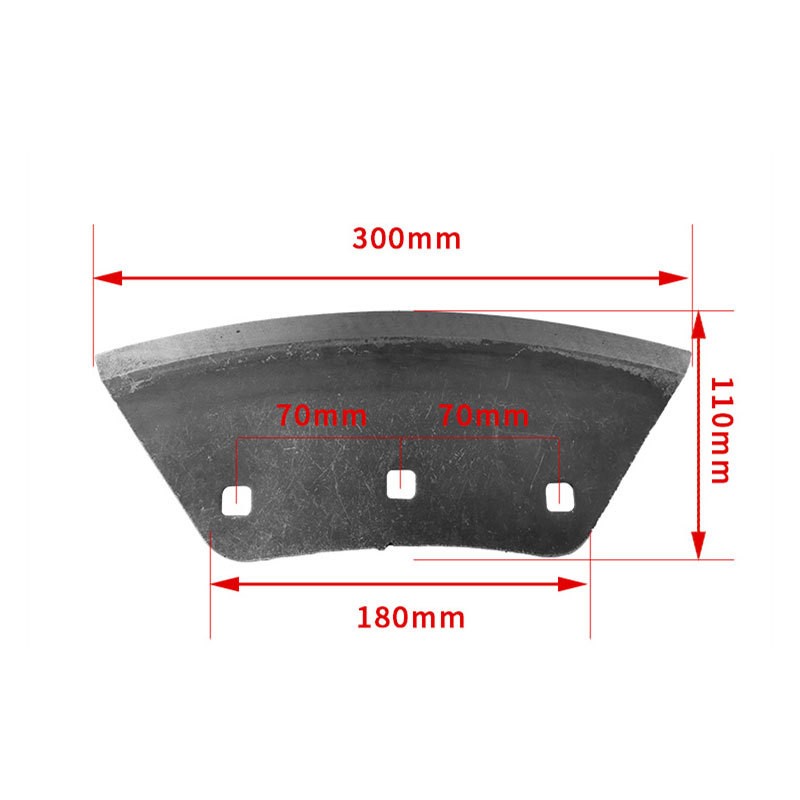

We pay attention to the geometry of the blade

The geometry of the blade is an equally important factor. The optimal shape provides a smooth and uniform incision, without unnecessary efforts and risks of the tool breakdown. The blades with the correct shape are firmly fixed in hydraulic boards, preventing their premature wear. Incorrect geometry can lead to overloading the tool and its breakdown.

Proper use and replacement of blades

Despite the high quality of the blades, proper operation plays a key role. It is recommended to regularly check the blades for wear and immediately replace them when chips, blunts or other damage appear. The correct installation of blades according to the manufacturer's instructions is the key to the safety and efficiency of the hydraulic boards. Failure to comply with these simple rules can lead to injuries and significantly reduce the life of the tool. Remember that replacing blades is not just a substitution of parts, but a guarantee of safety and quality of your work.