The crusher blade

The crusher blades are an important, but often inconspicuous detail of many mechanisms, from kitchen combines to huge industrial enterprises. They are responsible for grinding, crushing various materials - from vegetables to rocks. Understanding the device and the principle of operation of the blades of the crusher will help us assess the complexity and accuracy of these small, but strong assistants.

Varieties and materials of blades

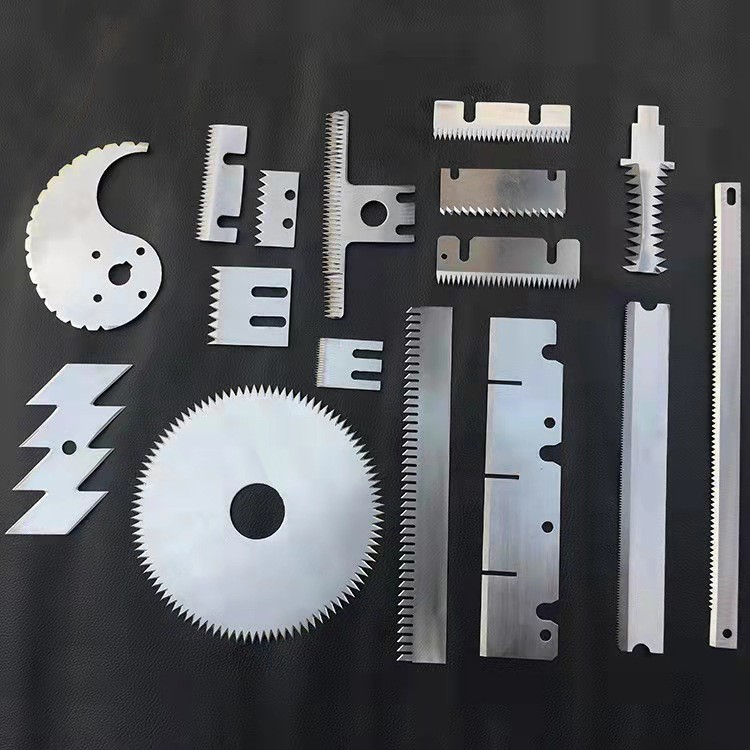

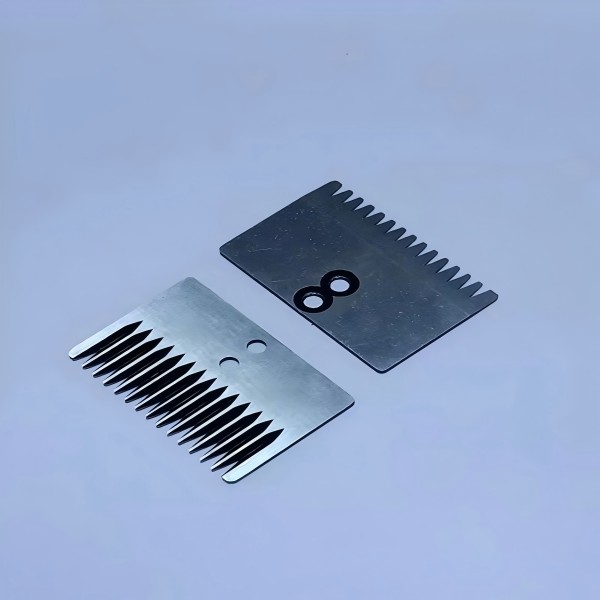

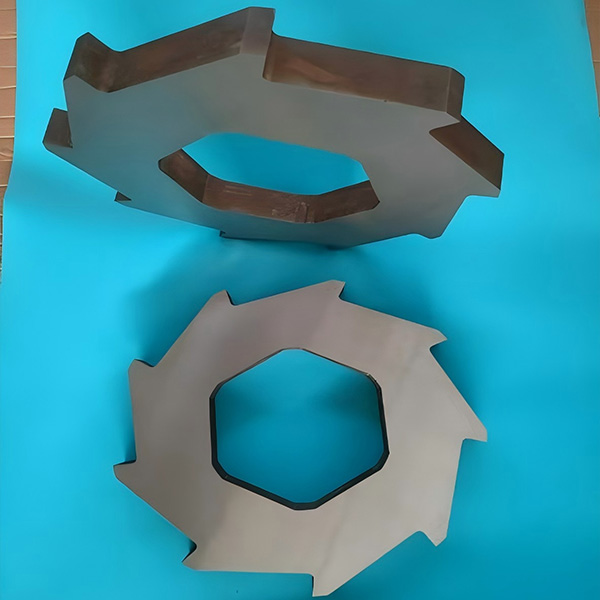

Different tasks require different tools. The crusher blades can be made of various materials: from durable steel for working with solid substances to softer metals suitable for grinding softer products. There are also blades from special alloys that provide optimal strength and durability with specific types of processing. The shape of the blades also varies: from sharp knives for thin grinding to a variety of gear structures that provide crushing. Some crushers have rotating drums with many blades that act as multifunctional hammers. The choice depends on what exactly needs to be crushed.

How crushers blades affect the quality of the result

The quality of crushing is directly related to the quality of the blades. Sharp and properly sharpened blades provide uniform grinding, while maintaining the structure and properties of the source material. Dull or damaged blades can lead to uneven crushing, chopping in pieces, as well as to wear of the entire crusher. Therefore, it is important to sharpen or replacement of blades in time so that the device works efficiently and safely. This not only saves time and energy, but also retains the integrity of the mechanism itself.

Care and safety when working with blades

Proper care of the crusher blades is the key to their long service. Regular lubrication and cleaning, as well as timely sharpening (or replacement) are important aspects. Do not forget that working with moving blades is always a risk of injuries. Therefore, always follow the manufacturer's instructions, follow the precautions and use protective equipment (gloves, protective glasses). Do not try to grind materials that are not suitable for this type of crusher, because this can lead to breakdowns and injuries. Safety should be in the first place when working with any mechanism containing crushing blades.