Blade for crushers

Crushes blades are, in fact, tools that play an important role in the process of grinding various materials. Imagine a huge bunch of grain that needs to be turned into small flour. Or, for example, large pieces of rock, which need to be crushed to the desired size for further processing. In both of these cases, crushers blades come to the rescue.

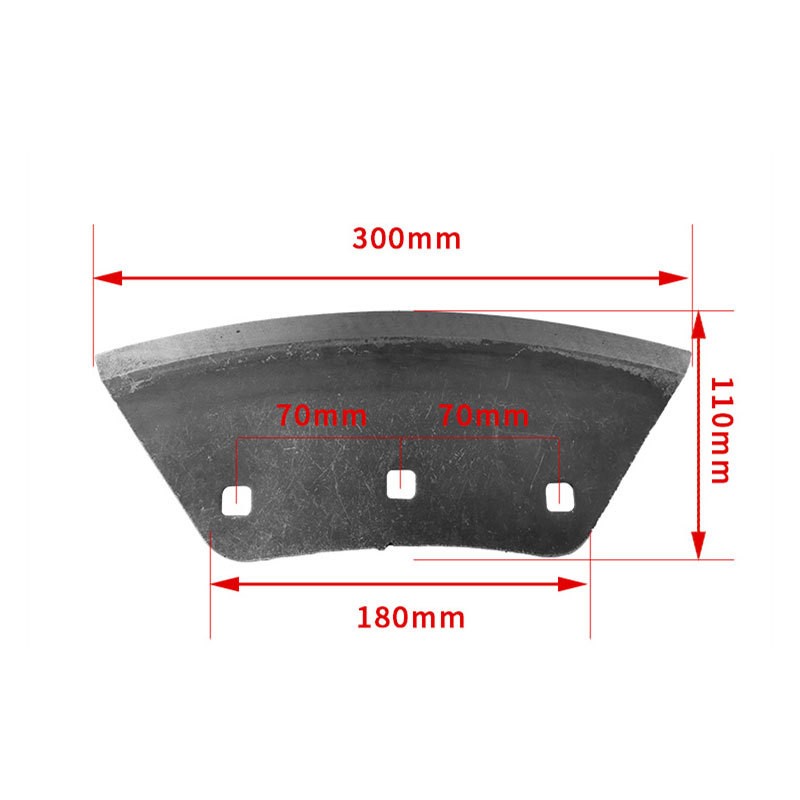

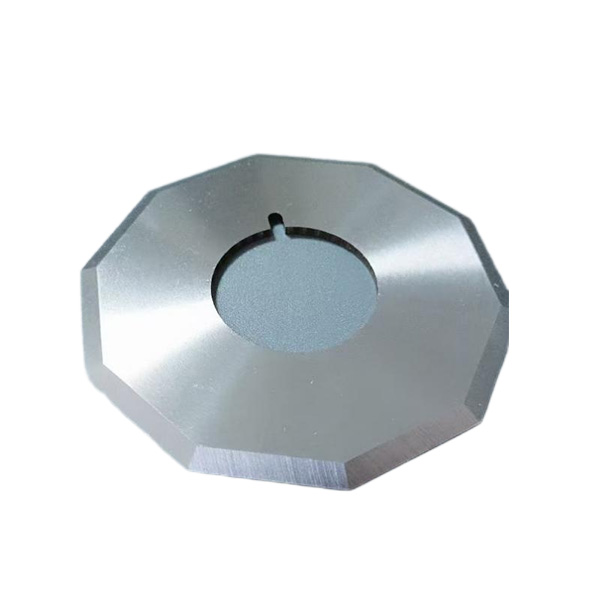

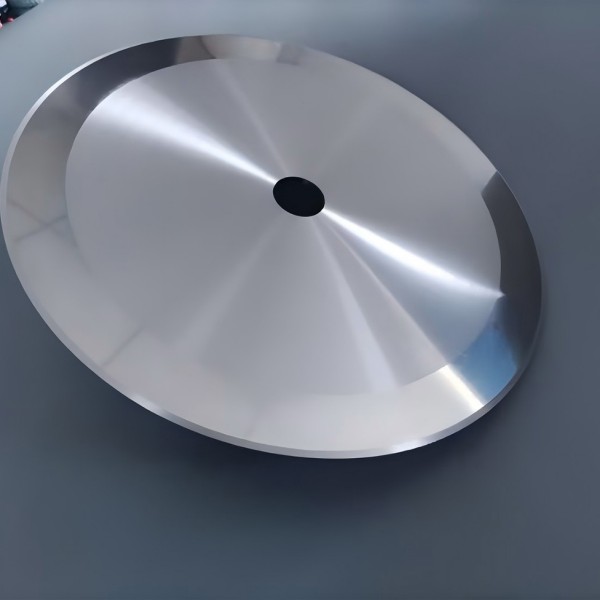

A variety of forms and materials

Crushes blades are of various shapes and sizes. It all depends on which material is to be crushed and with what degree of grinding you need to achieve. There are blades resembling sharp knives, and there are blades with a gear surface, designed for more rough crushing. The material for the manufacture of blades can serve as various alloys of metals, which should have high strength and wear resistance. After all, they work in conditions of heavy loads and constant friction. A good blade is the reliability and durability of the entire crusher.

The choice of blades is the key to effective work

The right choice of crumbling blades is the key to a successful and effective grinding process. It is necessary to take into account the type of material processed. For fragile materials, for example, glass or ceramics, blades with high acuity and strength are suitable. And for more solid materials, such as metals or stone, more durable blades are required that can withstand significant loads. It is also important to pay attention to the material from which the blade is made, and its geometric features are a guarantee of a long service life of the equipment.

Care for blades - the key to a long life of technology

Proper care of blades is an equally important aspect than their choice. Regular sharpening and replacing worn blades extend the service life of the crusher, ensure the safety and high efficiency of the process. If the blades are stupid, the load on the crusher increases, this can lead to breakdowns, and the efficiency of work is significantly reduced. Therefore, timely maintenance is not only a guarantee of the working capacity of the crusher, but also the saving on the repair.