Usually they are made of highly chubs of cast iron or nickel solid alloy with extremely high wear resistance and impact resistance. They evenly mix the concrete in a forced mixer, rotating at high speed, and at the same time withstand friction and strokes of materials with wear -resistant blades for the mixer with extremely high wear resistance and impact resistance.

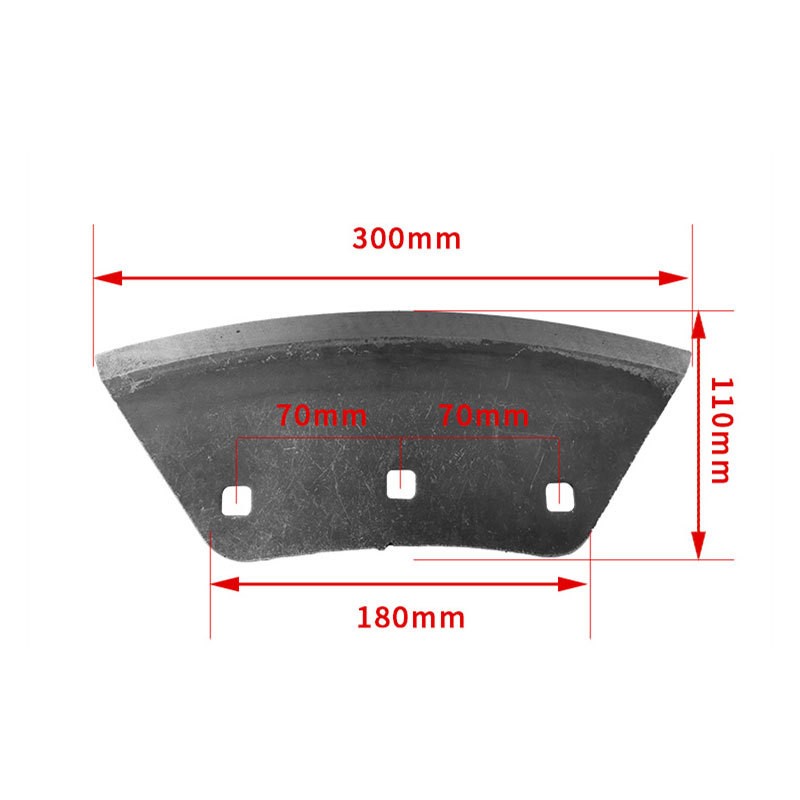

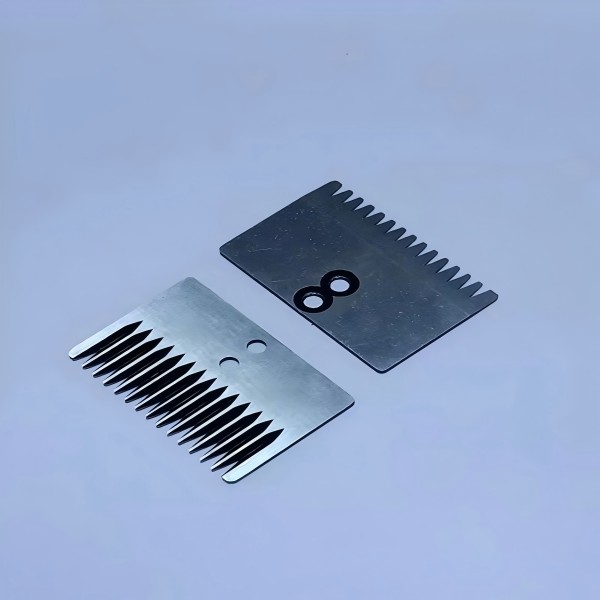

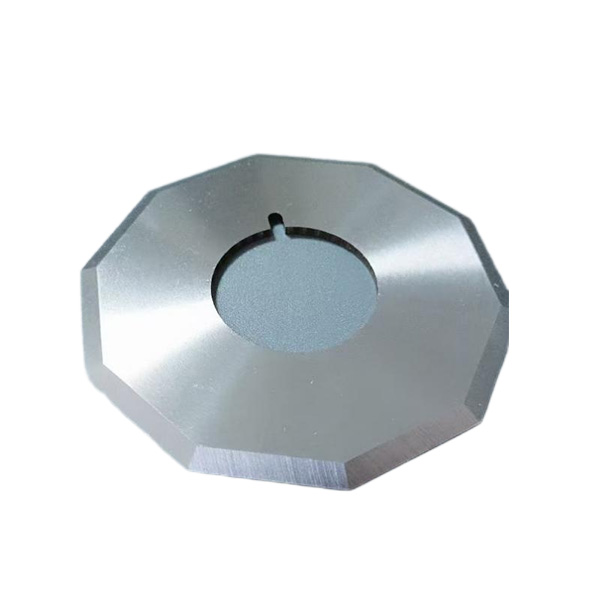

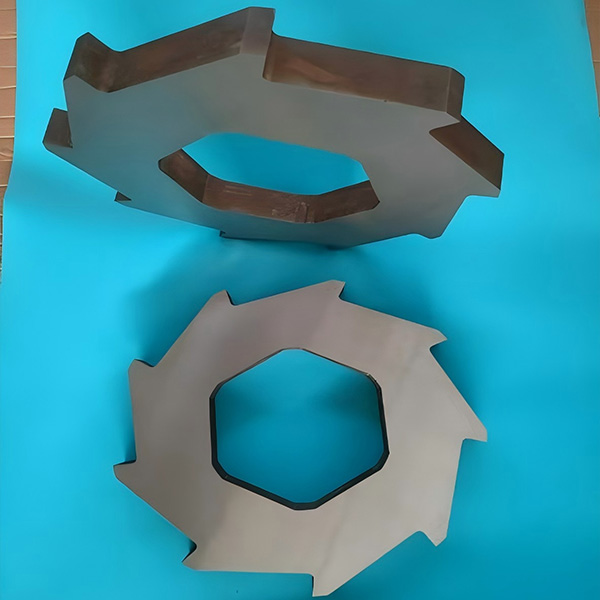

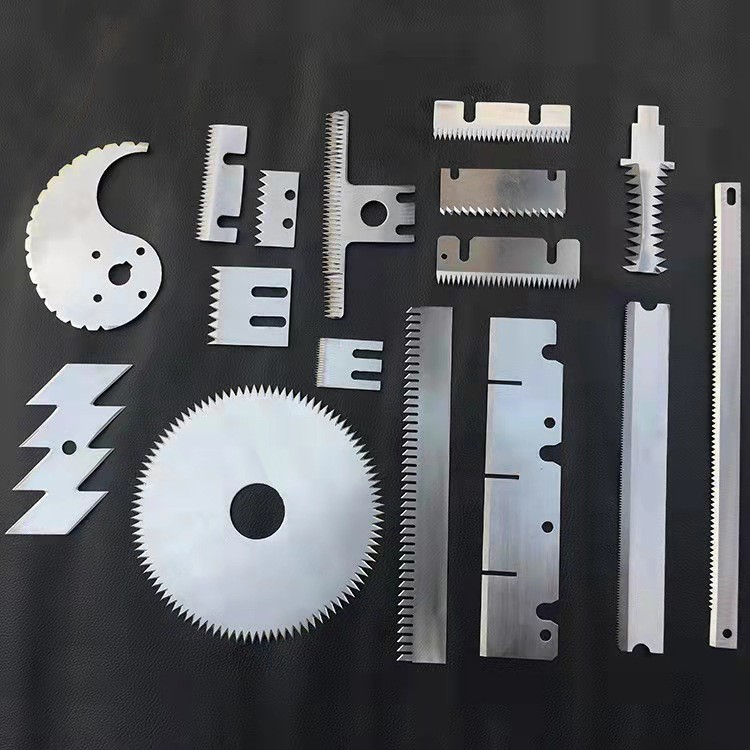

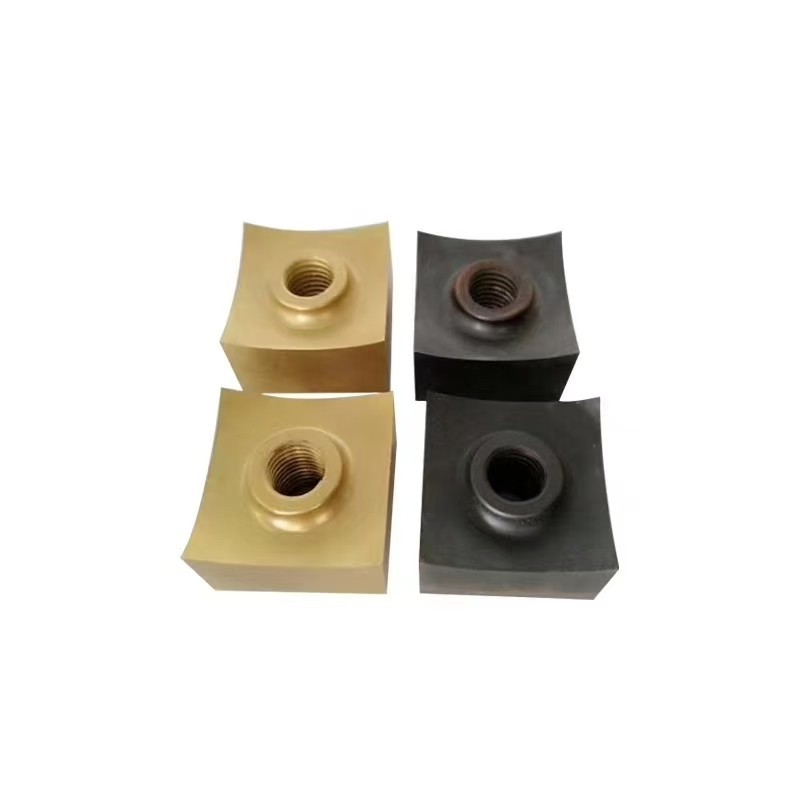

Usually they are made of highly chubs of cast iron or nickel solid alloy with extremely high wear resistance and impact resistance. They evenly mix the concrete in a forced mixer, rotating at high speed, and at the same time withstand friction and strokes of materials with wear -resistant blades for the mixer with extremely high wear resistance and impact resistance. They evenly mix concrete due to high -speed rotation in the forced mixer, while withstanding friction and strokes of materials. The design of the mixing levers includes thickened steel plates and reinforcing rods, which increases their overall strength and wear resistance. They are fixed on the inner wall of the mixer, support the mixing blades and bring them into rotation, providing a stable mixing process. Fotterovs are usually made of wear -resistant rubber or high -horn alloys and are installed on the inner wall and bottom of the mixer to protect the case from direct abrasion with concrete materials. These inserts are usually made of high -strength wear -resistant materials, such as high -marganized steel, alloy steel, etc., which have high hardness and wear resistance, and can withstand the impacts and abrasion of materials during mixing. The wear -resistant lining of the loading bunker is made of wear -resistant alloy steel or composite material, which has good strength and resistance to abrasion, so that raw materials, such as sand and gravel, do not cause abrasion of loading bunker when entering the mixer. Concrete's cylinder bushings: in the process of pumping concrete, these bushings are in direct contact with concrete and push it forward, which requires extremely high wear resistance and resistance to pressure, and are usually made of special wear -resistant materials, such as ceramic alloys.

The use of these wear -resistant accessories not only extends the service life of mixing equipment, but also increases productivity and reduces operating costs.