Sharpening knives for a crusher of wood

Proper sharpening of knives for wood crushers is not only a guarantee of long and effective work, but also an important safety factor. Stepstood knives not only reduce performance, but also increase the risk of injuries. Imagine that you are trying to crush the branch using a dumb knife - this is not only hard, but can also lead to the fact that a piece of wood will bounce and injure you.

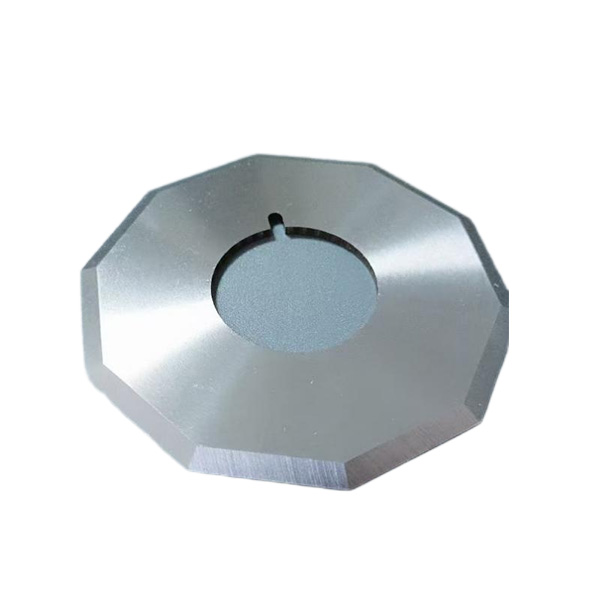

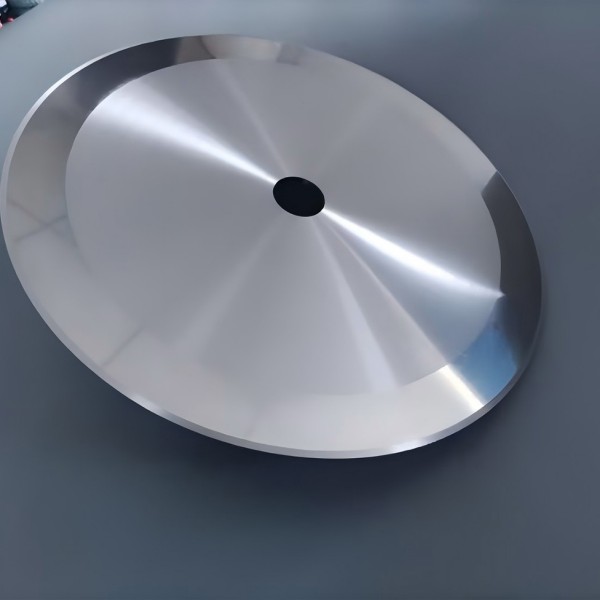

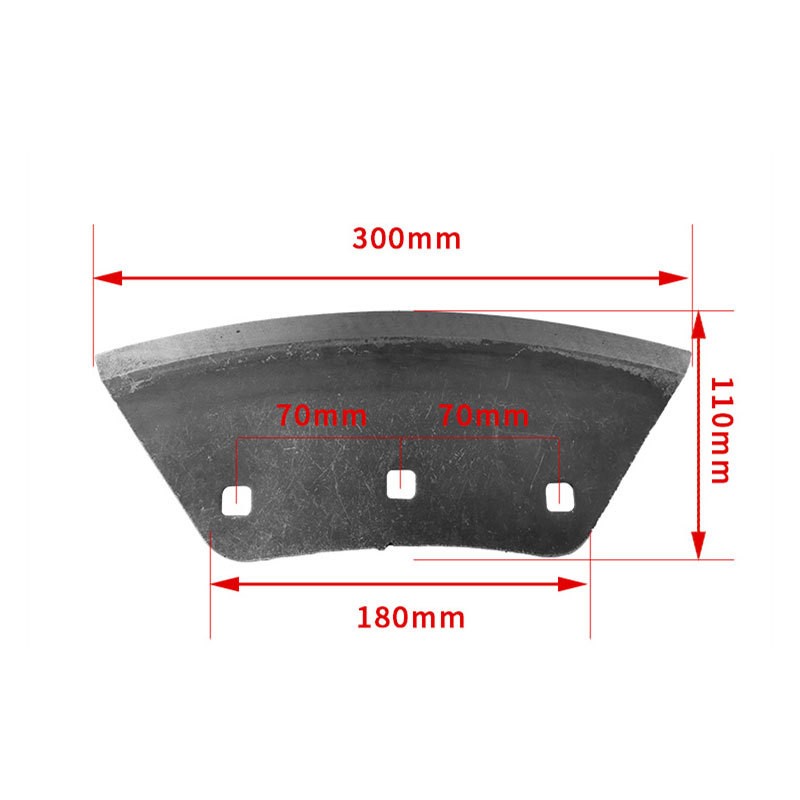

Selecting the correct sharpening tool

There are several ways for sharpening knives of the crusher, from simple to more complex ones. The easiest and most affordable way is to use abrasive stones or bars. It is important to choose the right abrasive material, given the thickness and shape of the knives. More complex options, such as electric sharpening machines, can be useful for more accurate and quick work, but require certain skills and knowledge. Do not be afraid to seek help from specialists if you are not confident in your abilities.

Sharpening technique and important recommendations

When working with crusher knives, it is important to observe safety precautions. Before starting work, make sure that the crusher is turned off and disabled from the electric network. Use protective gloves and glasses, especially when working with larger or sharp knives. It is very important to evenly sharpen all the cutting edges in order to avoid overload and breakdowns. If you notice that the knife bent strongly or has significant damage, it is best to replace it with new ones in order to avoid serious injuries.

Prevention and care for knives

Regular sharpening is not only a guarantee of safety, but also the key to a long service of knives. Frequent checks of knife sharpness will help to avoid breakdowns and injuries. Check knives after each work cycle or as they dull. It is also important to provide knives for proper storage. After sharpening, make sure that the knives are stored in a place protected from moisture to prevent corrosion. And of course, follow the cleanliness of the crusher in order to avoid the accumulation of wood sawdust and congestion. This will prevent breakdowns and extend the service life of your tools.