Drushing spare parts: details without which it does not work

Crushes are indispensable assistants in various sectors, from processing construction waste to animal feed. But, like any mechanism, the crusher needs timely maintenance and replacement of worn -out spare parts. Without them, she will not be able to do her work efficiently and can even fail. We will figure out what spare parts most often require replacement.

The main types of spare parts for the crusher

The main spare parts that need regular verification and replacement include:

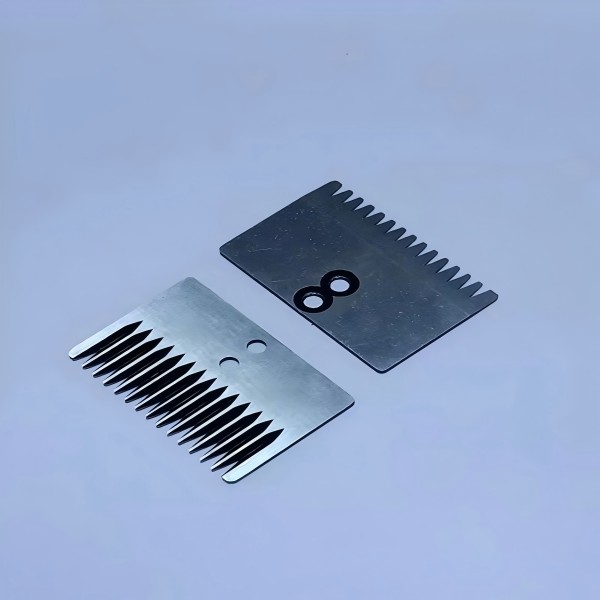

Working tools: hammers, knives, teeth, jaws - elements directly in contact with the material that needs to be crushed. As they work, they wear out and lose their severity, which reduces productivity and can harm the mechanism. It is these details that require the most frequent attention.

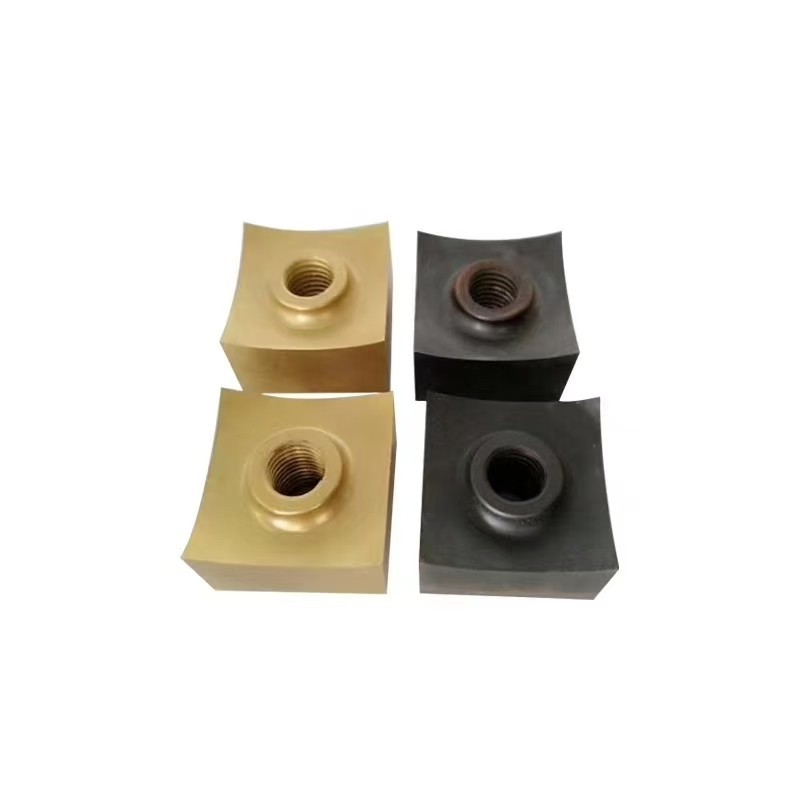

Bearings and ramparts: these details provide a smooth rotation of the crusher. If they are worn out, this will lead to overloads, noise and, ultimately, breakdown of the entire structure.

Fasteners: bolts, nuts, washers - these are inconspicuous, but important details that provide reliability of the entire structure. Weak or damaged fasteners can lead to emergency situations.

Air and hydraulic components (if any): if the crusher is equipped with such systems, it is necessary to check and change worn hoses, valves, pumps and so on.

Why is it important to change spare parts in time?

Replacing worn out spare parts not only extends the service life of the crusher, but also ensures the safety of the work. Wondered details can bring to:

Damage to the mechanism: jamming, breakdown of shafts, deformation of corps elements - all this can lead to serious breakdowns and repair costs.

Damage to the materials that are processed: stupid knives or worn hammers will not provide high -quality grinding, and this can lead to problems in the subsequent process.

Reducing performance: insufficiently sharp tools will slow down the grinding process, which will lead to a loss of time and money.

The emergence of emergency situations: breakdowns can occur suddenly, and this can lead to staff injuries.

How to choose quality spare parts?

When buying spare parts for a crusher, it is necessary to pay attention to the reputation of the supplier and the compliance of parts with technical characteristics. Use proven sources to avoid the acquisition of poor -quality details that will eventually lead to additional problems.