Factories for the production of knives with jagged ends in China

China is the largest manufacturer of knives in the world. The variety of products is amazing - from simple kitchen knives to specialized tools. Among this great diversity, there are knives with jagged ends. But what is behind this seemingly simple tool? How do factories producing this specific products work?

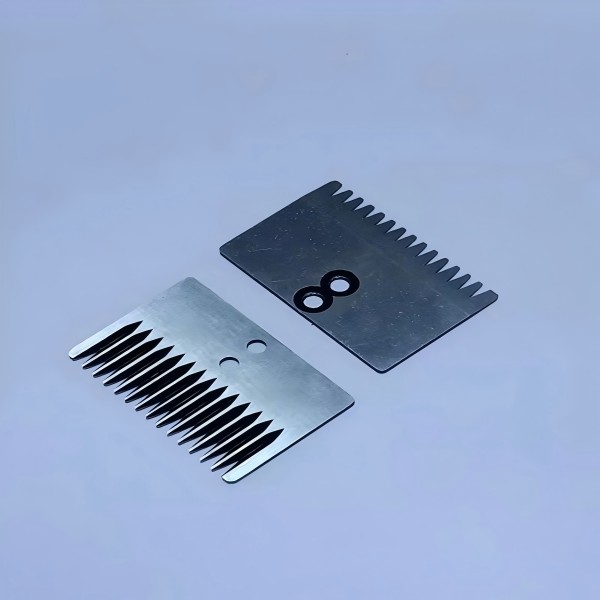

Technologies for the production of jagged blades

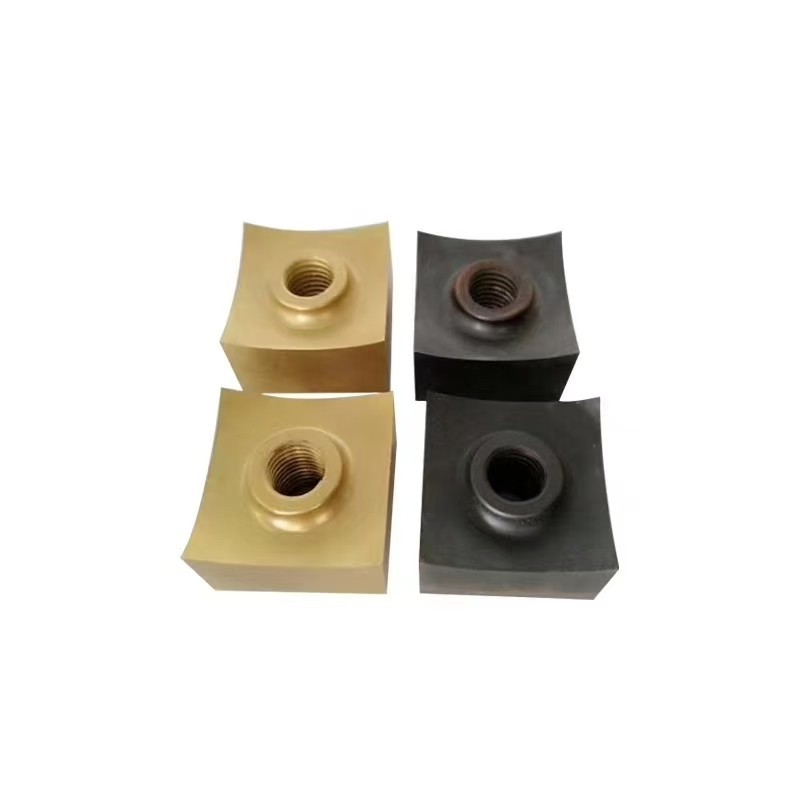

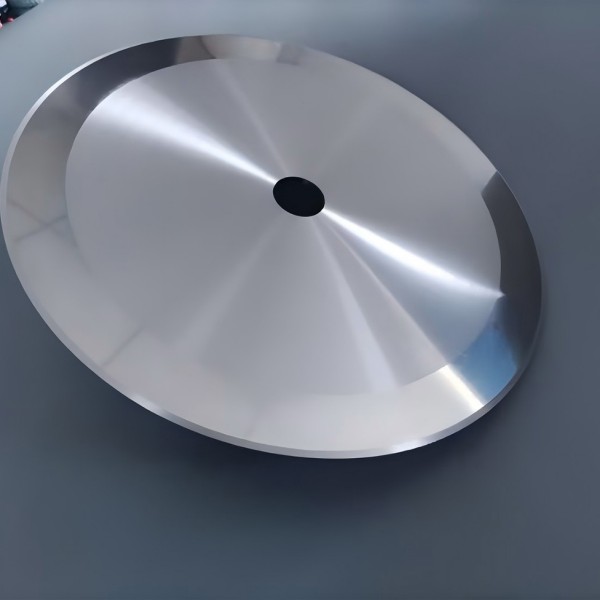

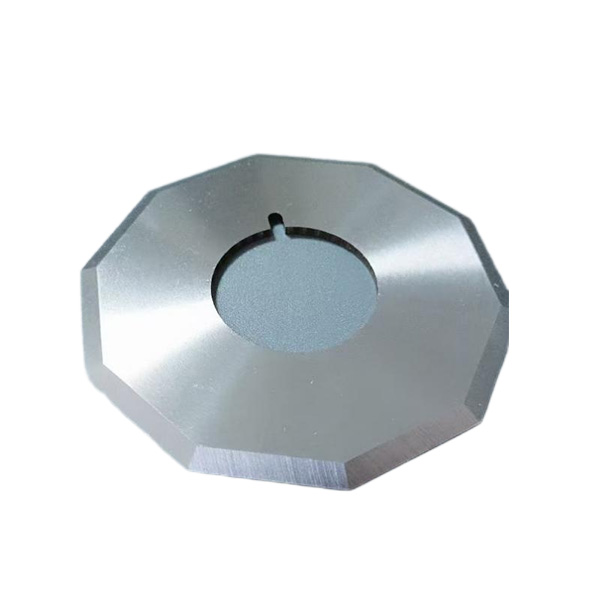

Modern Chinese factories are equipped with advanced technologies. From the choice of high -quality steel to accurate sharpening and processing - each stage of production is carefully monitored. Special equipment allows you to create zabins of the desired shape and depth, guaranteeing that the knife will effectively cope with its task. Workers trained in high standards perform complex operations that require accuracy and attention. Qualified experts monitor compliance with all safety rules in production.

Variety of the use of jagged knives

The jagged ends of the knives are in demand in various fields. It can be knives for processing wood, for various construction work, knives for metal processing or even special knives for certain tasks in everyday life. For example, their use is found in decorative crafts, where the jagged edge gives the products a unique texture. Particular demand is observed for jagged knives for fishing, where sharp zabins help to reliably fix the catch.

Quality and safety in Chinese industries

Chinese factories for the production of knives strive for high quality of their products. This is achieved not only by modern technologies, but also by responsible practices. The emphasis is on the use of safe equipment and compliance with quality standards. In addition, manufacturers take care of the security of their employees, providing appropriate protection funds and conducting briefings. This means that consumers can be sure that the knife made in China meets certain quality standards and is safe to use.