Disk knives for roller cutting

Disk knives are an indispensable tool in various fields of production and processing of materials. They are used for accurate and effective cutting, especially when it comes to roller cutting. Imagine giant scissors, but instead of blades they have a rotating disk with sharp cutting edges. This disk, combined with the roller mechanism, allows you to achieve impressive speed and quality of cutting, which makes discs indispensable in workshops for the production of paper, cardboard, textiles, even some types of wood.

Advantages of using disk knives

The main advantage is high speed and performance. Disk knives allow you to process large volumes of material in a short period of time, which significantly optimizes the production process. In addition, they provide high accuracy of cutting, which is important for many production tasks. The roller system allows you to evenly distribute the load on the knife, increasing its durability. Also, correctly selected disc knives contribute to the minimum wear of the material, which reduces losses and increases production efficiency.

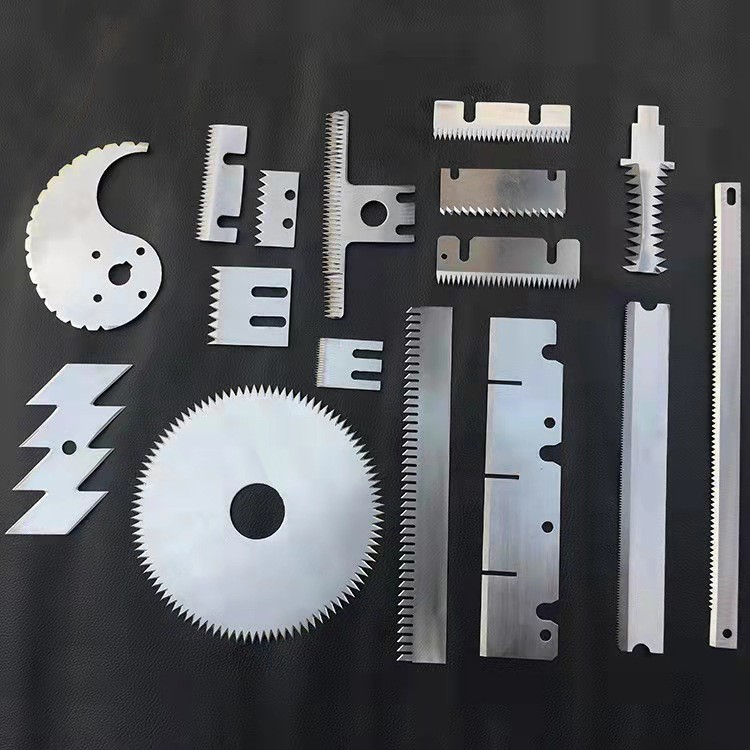

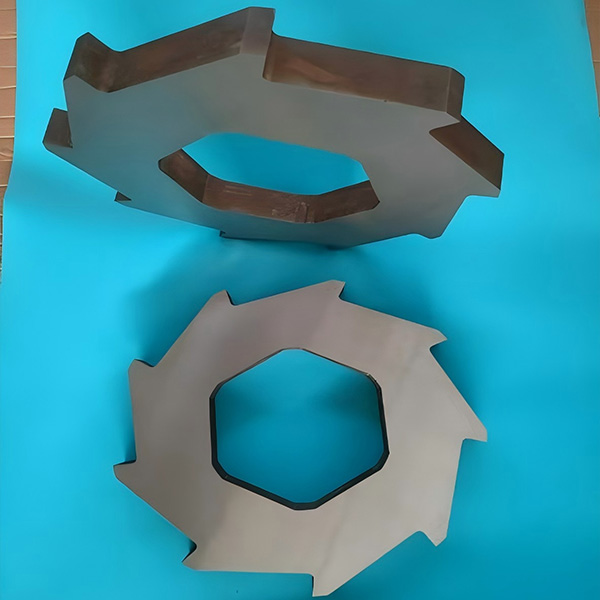

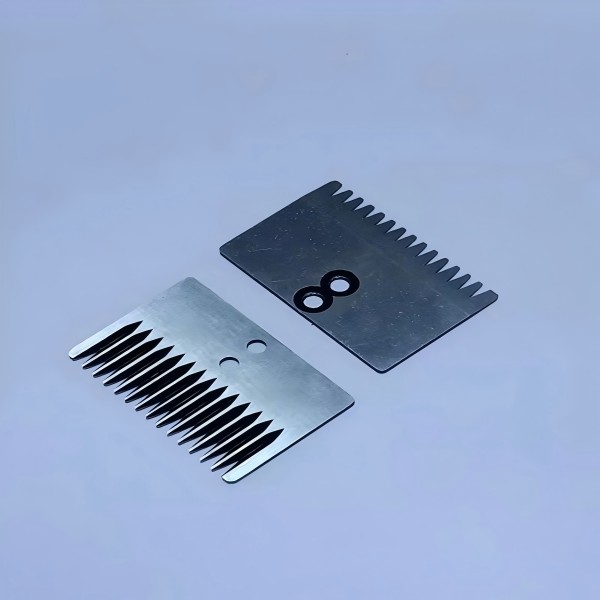

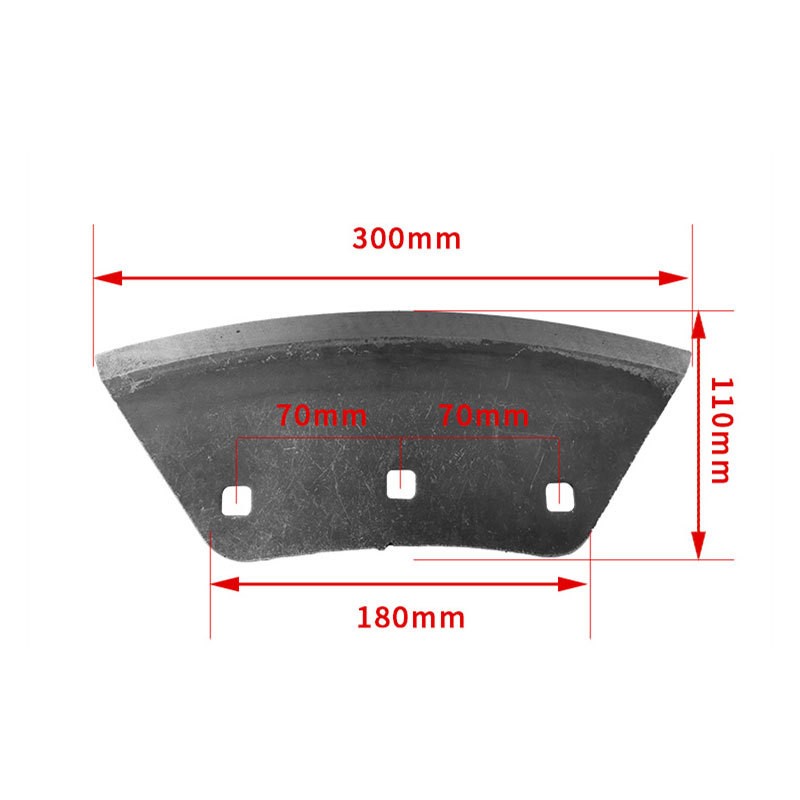

Types of discs and their use

The variety of discs is impressive. They can be made of various materials: from hardened steel to more specialized alloys that can withstand increased loads. The choice of material depends on the type of material that is subject to cutting. For example, for cutting thin cardboard, knives with high accuracy and high rotation speed are needed. At the same time, for the processing of more durable materials, for example, plywood or some types of plastic, knives are required with greater thickness and strength. Manufacturers offer a wide range that allows you to choose the best option for specific tasks.

Disk knives care and maintenance

Proper care is the key to long and efficient operation of disc knives. Regular sharpening or replacing knives are extremely important stages. This will maintain their severity and prevent breakdowns. It is also important to monitor the state of the roller system and make a lubricant in a timely manner. Compliance with these recommendations will avoid expensive breakdowns and ensure the continuity of the production process, which will significantly increase the overall efficiency of work.